Pros and Cons of Digital Work Instructions

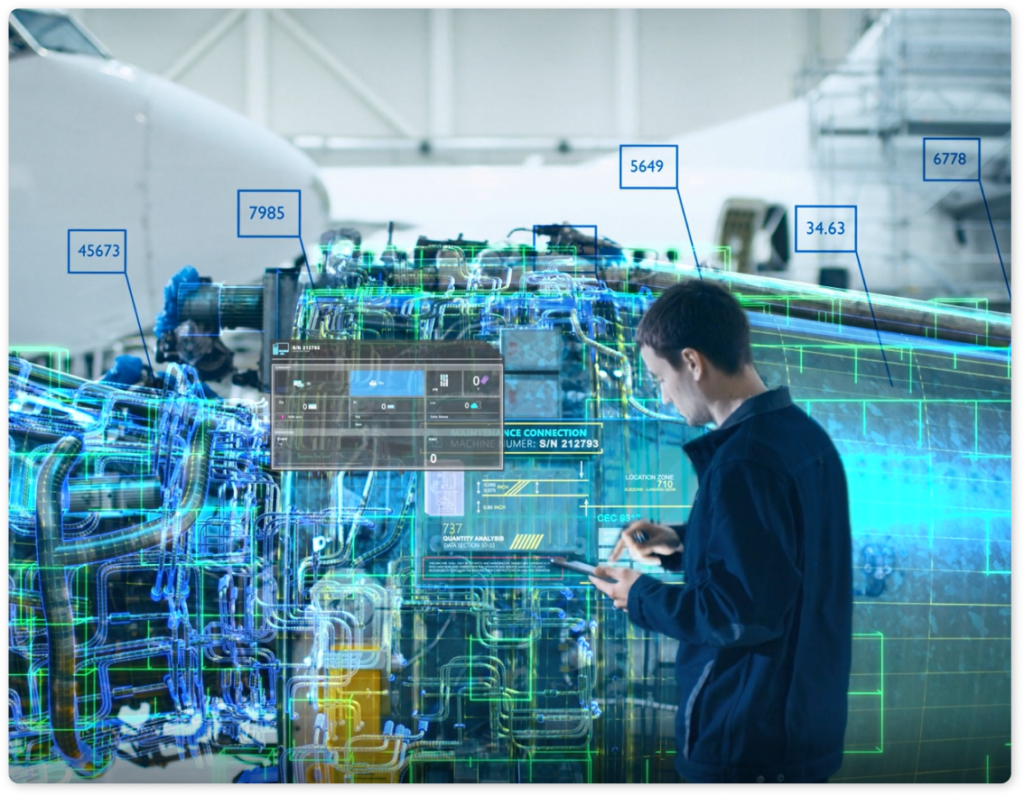

The world is now transforming, and people are moving towards digitized life. IoT, industry 4.0, smart factories, and now the upcoming industry 5.0 is taking over the technological world. However, each of these technologies has their own benefits and challenges. Similarly, digital work instructions are transforming the way manufacturing processes and workflow are managed, providing a range of benefits over traditional paper-based methods. However, just like any technology, they come with their own set of pros and cons. Understanding these advantages and shortcomings is important for organizations who are considering full implementation of DWIs. That is why we are here to help you out. In the blog Typical Applications of Digital Work Instructions we learned the different industries such as healthcare, manufacturing, etc. where we can use DWIs and how implementing these work instructions is changing these sectors. Here, we will analyze the pros and cons of using digital work instructions in the factory.

Pros of Digital Work Instructions

There are a lot of benefits that digital work instructions can provide such as increased accuracy, consistency, real-time updates and many more. Thus, here are 5 pros of digital work instructions.

1. Improved Accuracy and Consistency

DWIs help in minimizing errors and bringing standardization approach to the tasks and processes. They significantly reduce the chance of human error by being able to give detailed and accurate instructions. Moreover, the visual aids and interactives processes relatable to DWIs also help in better understanding, execution and accuracy. This digitized set of instructions also ensures all the workers work in the same way ultimately having consistent outputs.

2. Real-Time Updates and Flexibility

The work instructions can be used for on-spot revision and adaptability. Use of new updates can be easily made in real-time while ensuring that workers are always informed and up to date. This is particularly true when there are constant changes in design or process enhancements. Additionally, the DWIs can also be modified quite easily for more than a few tasks, shift patterns or products making them perfectly suitable for dynamic and flexible production processes.

3. Enhanced Training and Onboarding

Including the digitized work instructions add interactivity to your training tools and consistency to your processes. They act as excellent training systems that help the new workers grasp the process quickly and thoroughly. Including these interactive features, such as quizzes and videos, can help improve the learning experience. They provide standardized instructions that make sure that each worker gets the same level and quality of training, producing consistency in production line and quality of products.

4. Data Integration and Analytics

Performance tracking and real-time feedback documenting can also be done through DWIs. These work instructions can be connected and synchronized with other digital systems to collect and analyze performance data. This data can further be used to identify areas for improvement and optimization of processes. The real-time feedback from workers helps in refining instructions and processes continuously.

5. Environmental Benefits

The most common and straightforward benefit of shifting to digital instruction from paper-based instructions is saving the environment. These instructions notably reduce the requirement for paper, making the manufacturing practices more sustainable.

Cons of Digital Work Instructions

Just like any other technology, digital work instructions also have some drawbacks. The drawbacks include their initial costs, cybersecurity risks, technical challenges and much more. Let’s see in detail what are the disadvantages of digital work instructions.

1. Initial Investment Costs

The biggest drawback of these work instructions is that implementing them requires a significant amount of initial investment in technology. You will need hardware such as tablets, wearable devices, and then the software. Also, these work instructions need regular upgrades and maintenance for both their hardware and software, which can add to the overall cost of the technology.

2. Technical Challenges

Then there comes the technical challenges and device durability. If there is no stable internet connection, then real-time updates and data synchronization are impossible. The connectivity issues can disrupt the production line and might disable access of workers to the on-hand instructions. If the industrial setting is extremely harsh then the devices are prone to damage. This can result in constant purchase of the same devices or shifting to more expensive hardware solutions suitable for such environments.

3. Cybersecurity Risks

Just like cloud computing and other cloud technologies, increased dependence on digital systems exposes the organization to cybersecurity threats. In such a case protecting confidential information and making sure of data integrity is a huge concern. Following cybersecurity regulations and standards can be difficult for some companies that do not have any idea about it and can require a lot of resources. Again, adding in to the costs.

4. Workforce Adaptation

Not everyone likes or is easily accustomed to modern technologies. Similarly, some workers might resist shifting from their familiar paper-based instructions to digital ones. The reasons can be many such as they do not understand the systems, are not skilled enough, and so on. To overcome this issue, an effective change in management strategies and extra training might be required, which will require time and resources.

5. Dependence on Technology

Technical issues are common such as system crashes and software bugs which can disturb the operations being performed. Making sure that the systems are working perfectly is important in such a case. Also, if the industry is excessively dependent on digital systems and does not have any other means of performing their tasks then it might lead to issues if the technology fails or becomes outdated.

Summary

Digital work instructions offer various benefits such as improvements in accuracy, real-time updates, and improved training capabilities. However, these also come with challenges such as initial investment costs, cybersecurity risks, and technical issues which cannot be neglected. So, organizations can make informed decisions about implementing DWIs in their processes to optimize them by carefully weighing the pros and cons of digital work instructions and see what works best for them.