Dropslab Technologies: Turning Failures into Opportunities with Failure Catalog

In the rapidly advancing industrial environment, minimizing errors and maximizing efficiency is imperative. If you are already familiar with Dropslab’s innovative solution, you might have read our article on Optimizing Shop Floor Operations with Digital Work Instructions. Building on that foundation, we are happy to delve deeper into one of our features which is the Failure Catalog within the Dropslab Sense platform. This functionality changes the way industries handle failures by providing noteworthy benefits to the frontline workers and improving the overall operational standards.

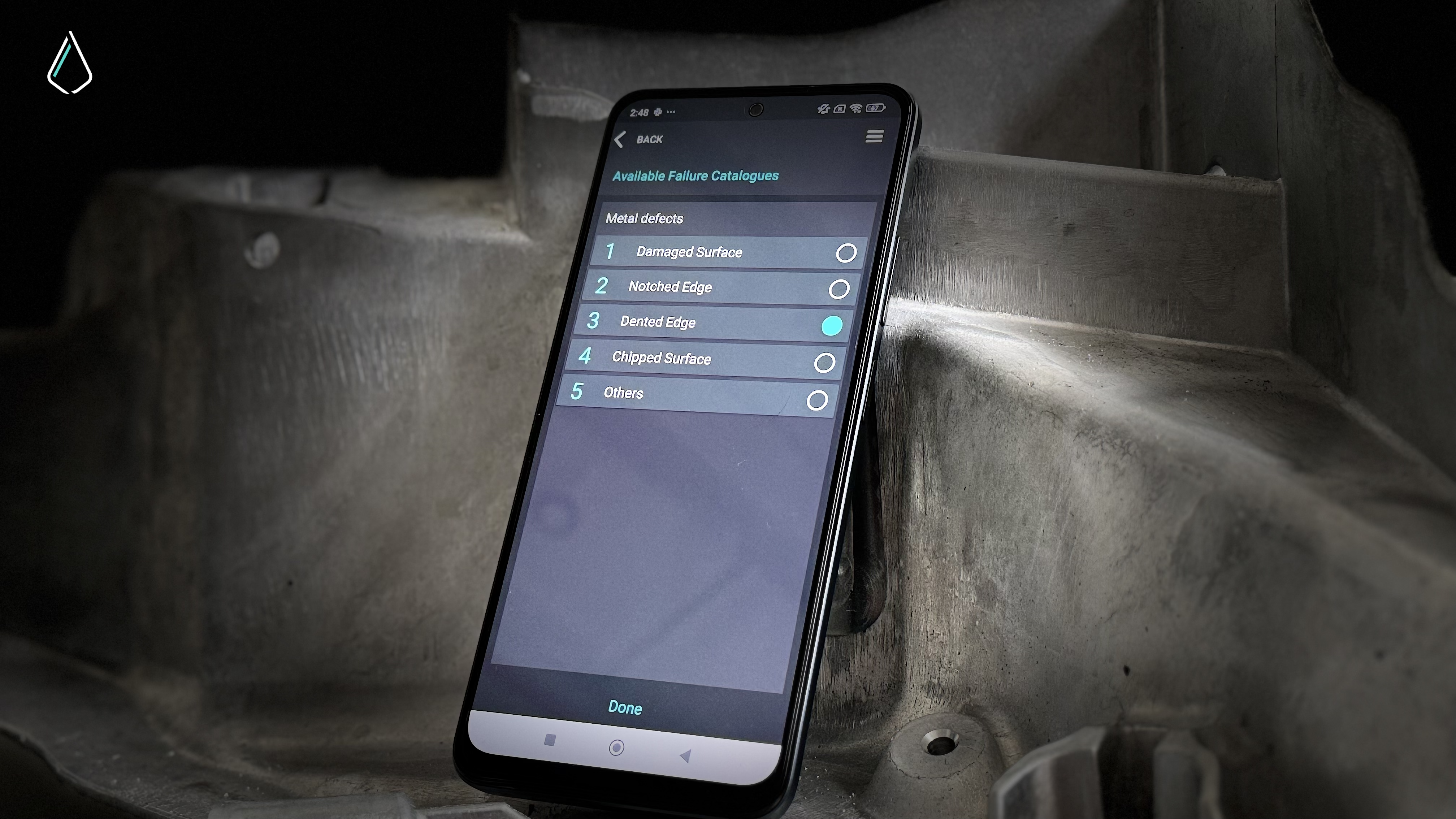

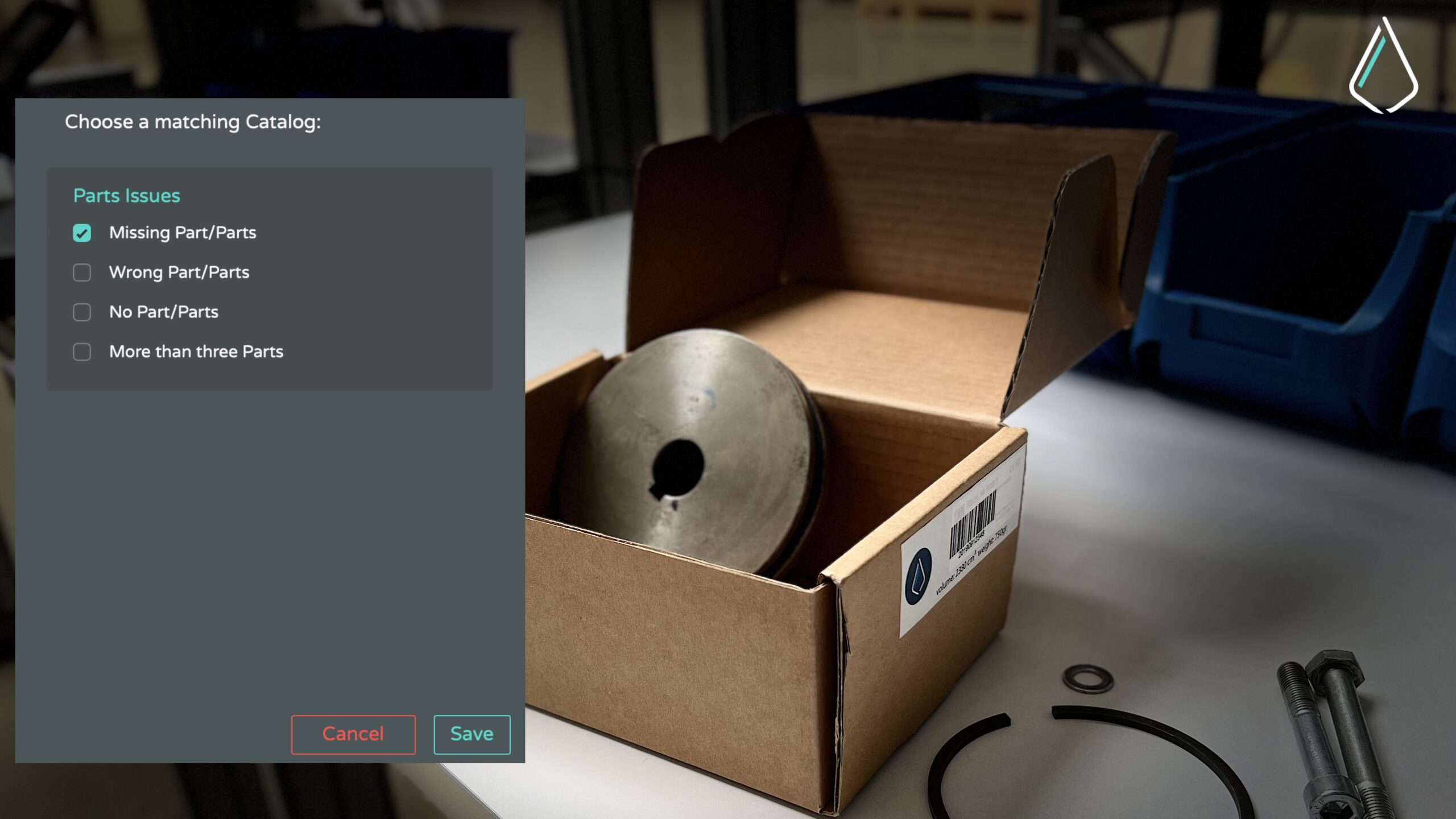

Failure Catalog is an important part of Dropslab Sense. It is designed to systematically analyze, document, and address issues or failures present in multiple tasks. This feature records important details like the type of failure and its quantity. It can detect manufacturing defects in a product, defects while transporting the product, and more. Using Dropslab’s Failure Catalog is easy, you have a thumbs up and a thumbs down option, if everything is good, the frontline workers can simply click on the thumbs up.

Failure Catalog is an important part of Dropslab Sense. It is designed to systematically analyze, document, and address issues or failures present in multiple tasks. This feature records important details like the type of failure and its quantity. It can detect manufacturing defects in a product, defects while transporting the product, and more. Using Dropslab’s Failure Catalog is easy, you have a thumbs up and a thumbs down option, if everything is good, the frontline workers can simply click on the thumbs up.

However, if they find any issues during inspection or assembly of a product, they can click on thumbs down and the Failure Catalog pops-up with failure categories to select from. These are then documented directly in the servers. This structured and detailed log of failure helps industries to identify and mitigate recurring issues which leads to enhances operational competence.

Why Dropslab’s Failure Catalog is Important for Workforce and Industries?

Using features like Failure Catalog can bring about multiple benefits for tech and other companies. According to a study by McKinsey, the industries that prioritize their failure analysis and constant improvement, they experience around 30% increment in customer satisfaction and 25% surge in total product quality and performance. This shows the direct importance of Failure Catalog and success for the business.

For the frontline workers, this feature enables them to improve their problem-solving skills as it provides them with insights into past issues and how they can be solved. The transparent record of failures makes sure that employees are responsible for their actions, which encourages them to follow standards and perform well. By learning about failure trends and solutions, workers can gain valuable knowledge about possible pitfalls and their best solutions. This helps with speeding up things as they can onboard processes efficiently and quickly.

Industries can improve quality control as this feature of Dropslab Sense allows them to identify failure trends that let them take proactive measures and improve quality control. By getting a report of damages and malfunctions, they can find root causes and resolve them, resulting in higher product and service quality. With the detailed failure issues report, management can make informed decisions that can help with process optimization, balanced resource usage, and implementing specific improvements. Many factories have strict rules, and this catalog helps follow these rules by keeping track of issues and decreasing downtime.

Summary

Dropslab’s Failure Catalog in Dropslab Sense is not just for recording issues; it is a tool to change workforce efficiency and follow industrial standards with ease. By carefully tracking and analyzing failures, factories can improve quality, save finances, and continuously improve. With growth in industrial technology, our Failure Catalog will promote innovation and excellence in tasks and processes.