Transitioning from Industry 4.0 to Industry 5.0: The Next Industrial Revolution

There have been many changes in the industrial sector with each industrial transformation. From the first industrial change consisting of mechanization to cyber-physical practices in Industry 4.0, each stage has brought revolutionary changes and improved performance through effective visual management and step media as we learned before. Now, we stand at the edge of another transformative phase which is Industry 5.0. This new stage is now taking the foundations build by Industry 4.0 a step further. This article discusses the shift from Industry 4.0 to 5.0, including the main differences, challenges and how the future is looking after Industry 5.0.

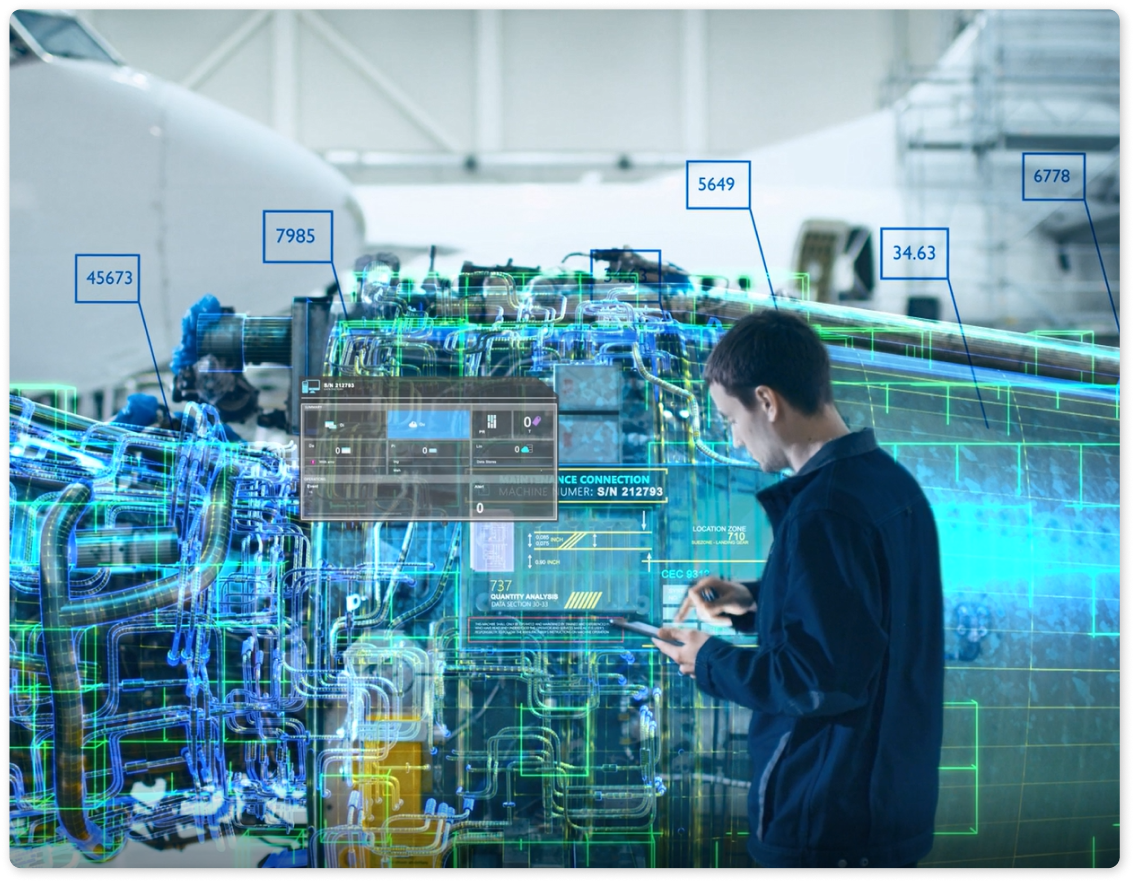

This fourth industrial revolution brought with it smart technologies in the industrial sector. It includes the IoT, AI, cloud computing, and big data in different production tasks. The main goal was to improve efficiency, optimize workflows, and minimize waste using automation and data-dependent decision-making. After Industry 4.0 factories started to become interconnected with machines and among workers. It helped in easy and real-time communication that made sure that the tasks are performed without issues and there is predictive maintenance. It changes the whole manufacturing process by producing smart factories that do not need any human interference.

The Emergence of Industry 5.0

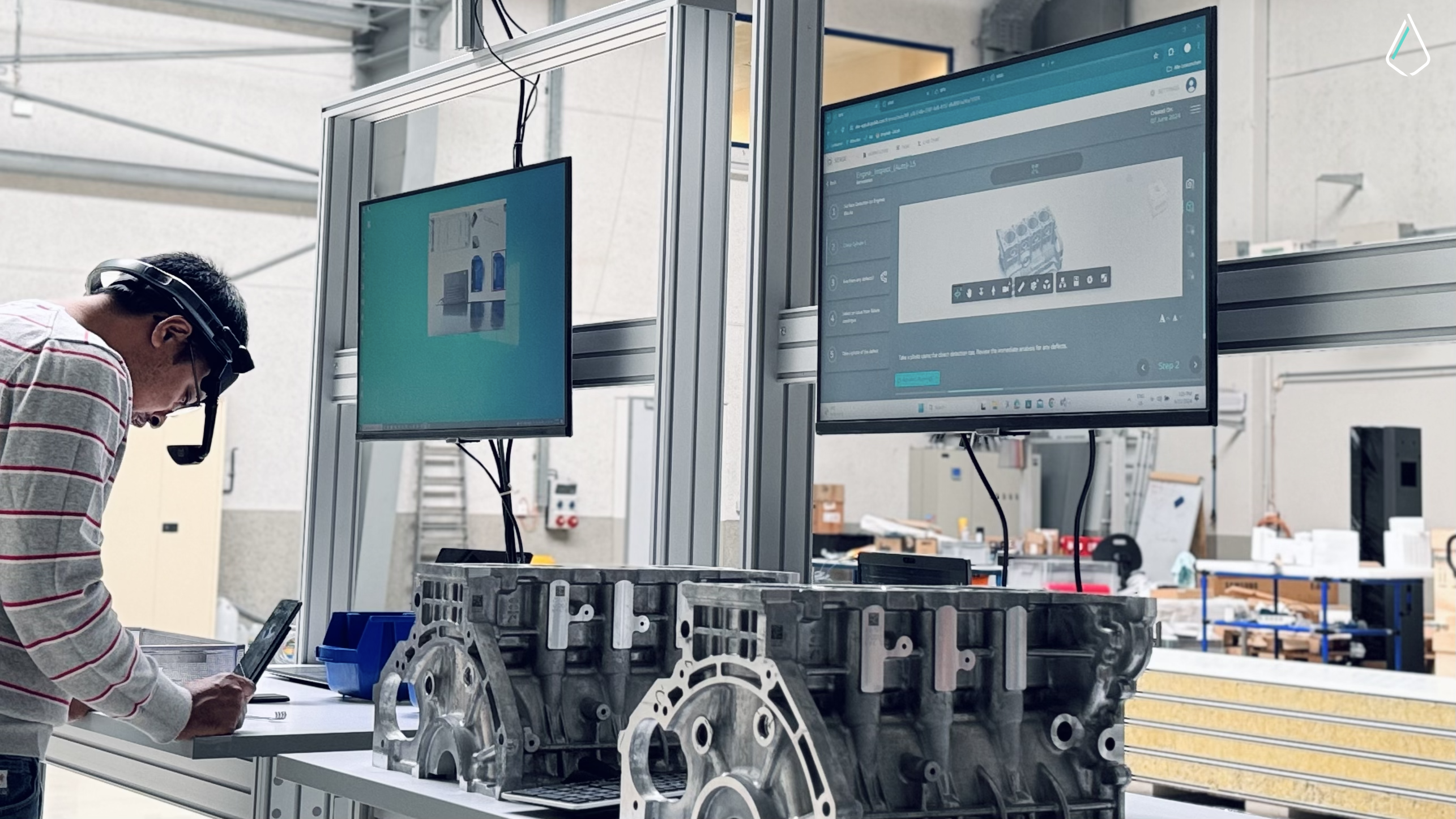

Industry 5.0 is not a fresh concept, but it is a continuation from Industry 4.0. It only introduces again some important concepts into the industry 4.0 which is the human touch. As per the European Commission:

“Industry 5.0 puts the safety and well-being of the workers at the centre of the production process”

Which means that it aims to balance the technological advancements while including environmental sustainability and human-centric values in the workflows.

Key Distinctions Between Industry 4.0 and Industry 5.0

Through industry 5.0 is only an upgradation of Industry 4.0, both these phases have some differences. The important differences between Industry 4.0 and 5.0 are:

| Aspect | Industry 4.0 | Industry 5.0 |

| Human-Robot Collaboration | It focuses on automation and machine efficiency | Emphasizes collaboration between humans and robots (‘cobots’) |

| Sustainability | Not a primary focus | Prioritizes sustainable practices and green technologies |

| Resilience and Adaptability | Rigid automation systems | Flexible and resilient manufacturing systems |

Driving Factors for the Shift

There are several factors that are driving the shift from Industry 4.0 to Industry 5.0. All these are there to improve quality and workplace environment together. These factors are:

| Factor | Description |

| Technological Advancements | Continuous advancements in AI, IoT, and robotics enable modern day human-robot interactions and efficient resource management |

| Societal Demands | Growing demand for high-quality, sustainably produced products; increased consumer awareness of environmental and social impacts |

| Workforce Well-being | Recognition of the need to enhance worker satisfaction and safety by involving humans more intimately in the production process |

Challenges in Shifting

Whenever we are moving from old technology to a new one there are always some challenges and risks. Similarly, when shifting from Industry 4.0 to Industry 5.0, there are several challenges. These challenges are:

| Challenge | Description |

| Technological Integration | Integrating advanced technologies into existing manufacturing systems requires significant investment and technical expertise. Making sure that both new and old systems are compatible can be difficult. |

| Skills Gap | As manufacturing processes become more advanced, workers with advanced technical skills are also required. Upskilling and reskilling workers can be challenged to minimize this gap. |

| Cultural Shift | Using a human-centric method requires a cultural shift within organizations. Organizations must prioritize workers’ well-being and sustainability. This might lead to changing old practices and mindsets completely. |

| Regulatory and Policy Support | To properly shift to Industry 5.0, supportive regulations and policies must be created that encourage innovation while making sure that those practices are ethical and eco-friendly. Governments and regulatory bodies must play an active role to accomplish these. |

How is the Future Looking After Industry 5.0

Industry 5.0 is bringing a new change which looks quite promising. The industry can become more balanced and efficient if Industry 5.0 is implemented. That is because it focuses on human and robot partnership, flexibility and sustainability. If industries are going to shift and follow these principles, then they can improve their productivity and climb the ladder in the market. They can also become part of the future world aiming for sustainability and equality.

Summary

The shift from Industry 4.0 to Industry 5.0 is not only just a technology upgrade. It is a complete strategy to change the world and move towards betterment. A tactic that focuses on human values and green practices along with industrial development. By emphasizing on coordination between equipment and humans, it guarantees to produce a more balanced and efficient industrial sector for the future.