10 Real-World Uses for the Poka-Yoke in Lean Manufacturing

It is a lean manufacturing method known as “mistake-proofing” or “error-proofing” a procedure or task is called Poka-yoke. When Shigeo Shingo first came up with it in the 1960s, Toyota used it as a component of the Toyota Production System (TPS). Poka-yoke may also be found in daily life, although most instances are so unremarkable that we are frequently unaware of its existence. Error-proofing in daily life includes spell check, which only keeps us from making stupid spelling mistakes, and safety measures that shield us from harm.

The 10 Use-Cases of Poka-Yoke in Daily Life

To understand the concept of Poka-Yoke, it is important to relate it with our daily life. So, here are ten real-world uses for the Poka-Yoke in our daily life.

1. Car Safety Functions

Many “error-proofing or poka-yoke” measures are built into cars to keep us safe while driving. When a door is open when the engine operates or when a person is in the passenger seat without their seatbelt on, many automobiles may beep or light up. These are a few instances of warning features that notify users of possible mistakes. In the past couple of years, we have seen tremendous advancements in safety technologies. These days, a lot of automobiles are fitted with sensors that warn drivers when they are getting too near to another car or object, or when they move out of their lane.

2. Treadmills

It is mandatory for treadmills to have a safety clip installed, which releases the treadmill when it is pulled. To protect users from harm, this safety function stops the treadmill if the person using it falls, that is if the person has the clip attached with their clothes.

3. Household Appliances

Numerous home appliances, including dishwashers, washing machines, dryers, and microwaves, include safety functions that stop them from working when the machine door is opened. These are a few examples of control functions, that hold off on starting the procedure until certain conditions like the door closing are fulfilled.

4. Garage Doors and Elevators

Most of the elevators and garage doors have sensors installed to keep the doors from closing if something or someone is standing in the way. This function is also available in other automated doors, such as garage doors and subway doors. When an elevator reaches its weight limit, many of them will also sound and stop working.

5. Spell-check Features

One popular, but usually unnoticed example of poka-yoke in everyday life is spell-checking. These technologies, which are a real example of “fool-proofing,” are built into our phones, software, and internet browsers that notify us to and frequently automatically fix spelling and grammar issues, saving us from appearing silly in our discussions.

6. Leak-proof Bottles and Travel Mugs

In certain cases, drinking from travel mugs and water bottles requires pressing and holding a button. This device keeps the contents from seeping out while an individual is not using the container to drink from it.

7. Power Outlets and USB Plugs

Numerous connectors, including USB and 3-pin connectors, are constructed to fix into outlets only in a certain way. This is a famous example of the “contact” method of poka-yoke, which takes benefits of an object’s physical traits to stop faults from being made.

8. Overflow Outlets in Sinks

A hole located just beneath the pipe in many sinks keeps water from spilling in the case that the drain becomes clogged.

9. Lawnmower Safety Bars

Lawnmowers sold in the United States are expected to feature a “dead-man control,” or a device that needs to be turned on to allow the blades to spin. This control usually comes in the shape of a lever fastened to the handle and that the user must press to start the lawnmower.

10. Wheelchair Wheels

When the wheelchair is not in use, the wheels are meant to lock. By doing this, it is ensured that the user of the wheelchair will not trip and fall or find themselves in a hazardous position with a runaway chair.

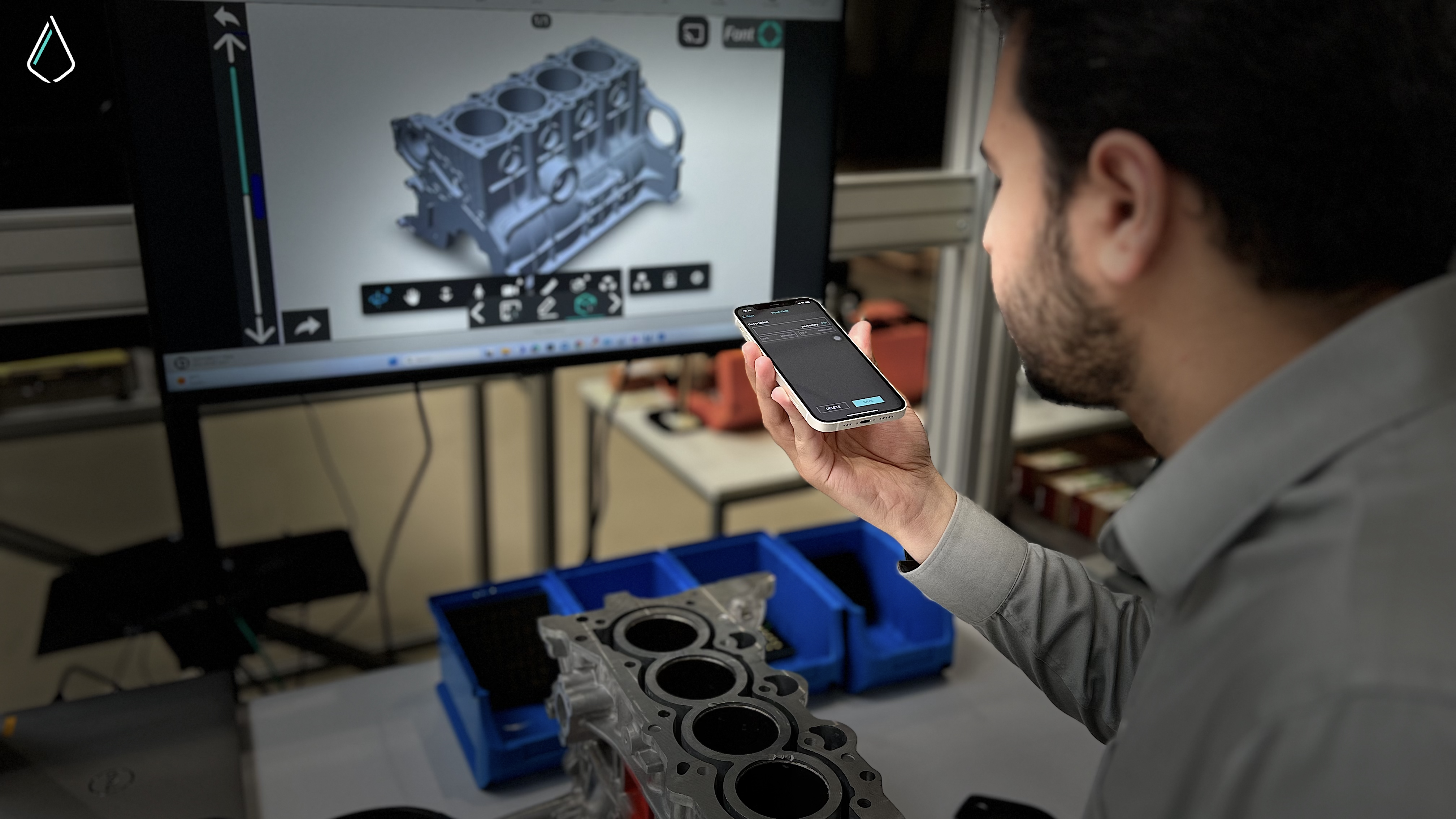

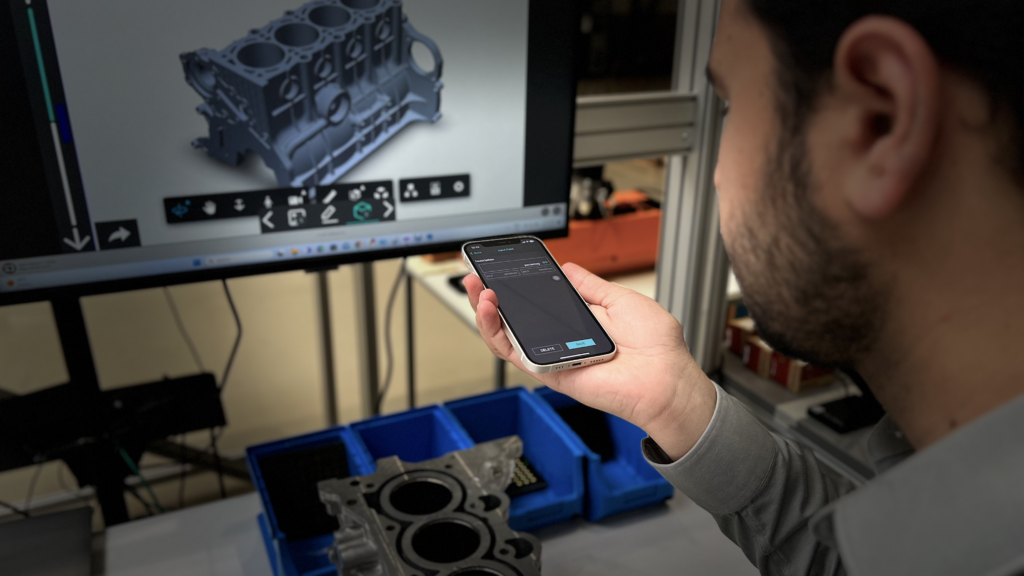

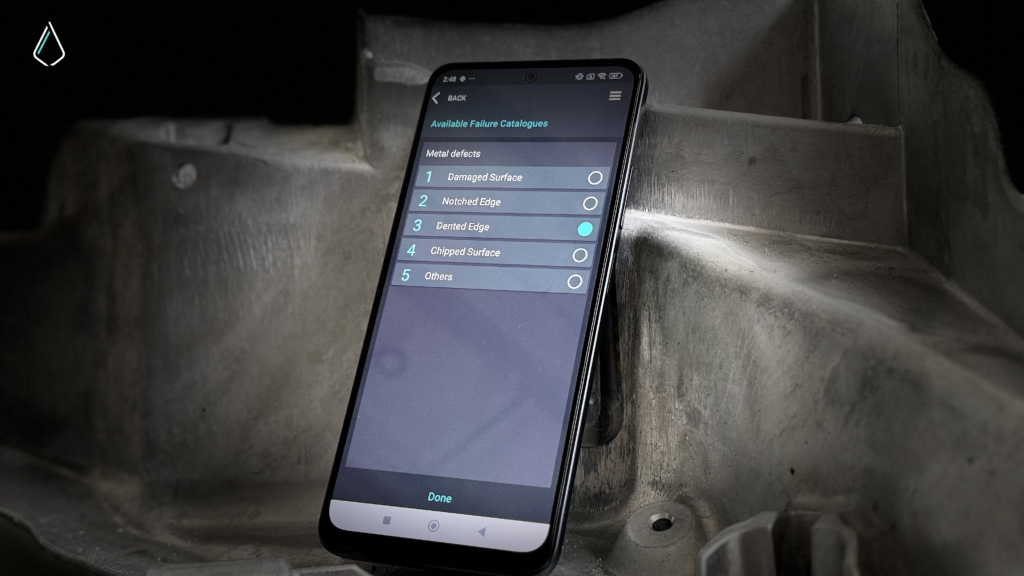

Error-proof your operations with Dropslab Technologies

Discover how manufacturers are using guided workflow applications to digitize quality management procedures and poka-yoke manufacturing by setting up a demo with us today!