AI in Manufacturing

A factory is no longer a physical entity where production happens. It is no longer a dream to establish a manufacturing unit that predicts issues, optimises workflows, and goes as far as to suggest innovative solutions. All this is now possible through integration of AI in manufacturing.

As industries and manufacturing processes evolve, we can find AI right at the core of this change. From automating routine tasks to redefining decision-making and skill requirements, AI is reshaping how factories operate.

In this blog, we explore AI in manufacturing, how it can transform the human workforce, what the future looks like, and the strategies manufacturers can adopt to capitalise on Return on Investment (ROI).

The Impact of AI on Manufacturing

Below mentioned are some of the areas in manufacturing experiencing significant advantage due to AI:

AI-powered predictive maintenance

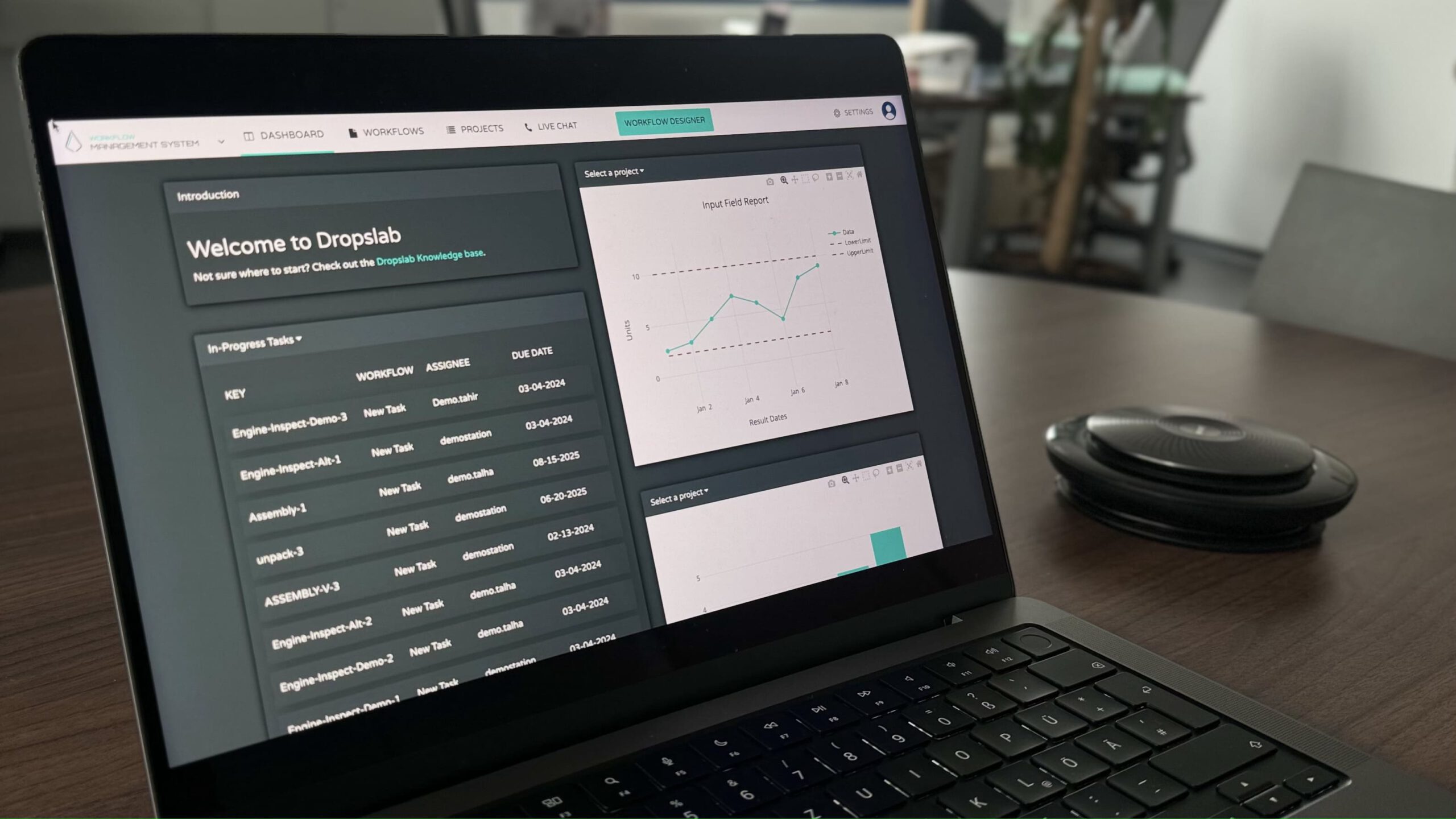

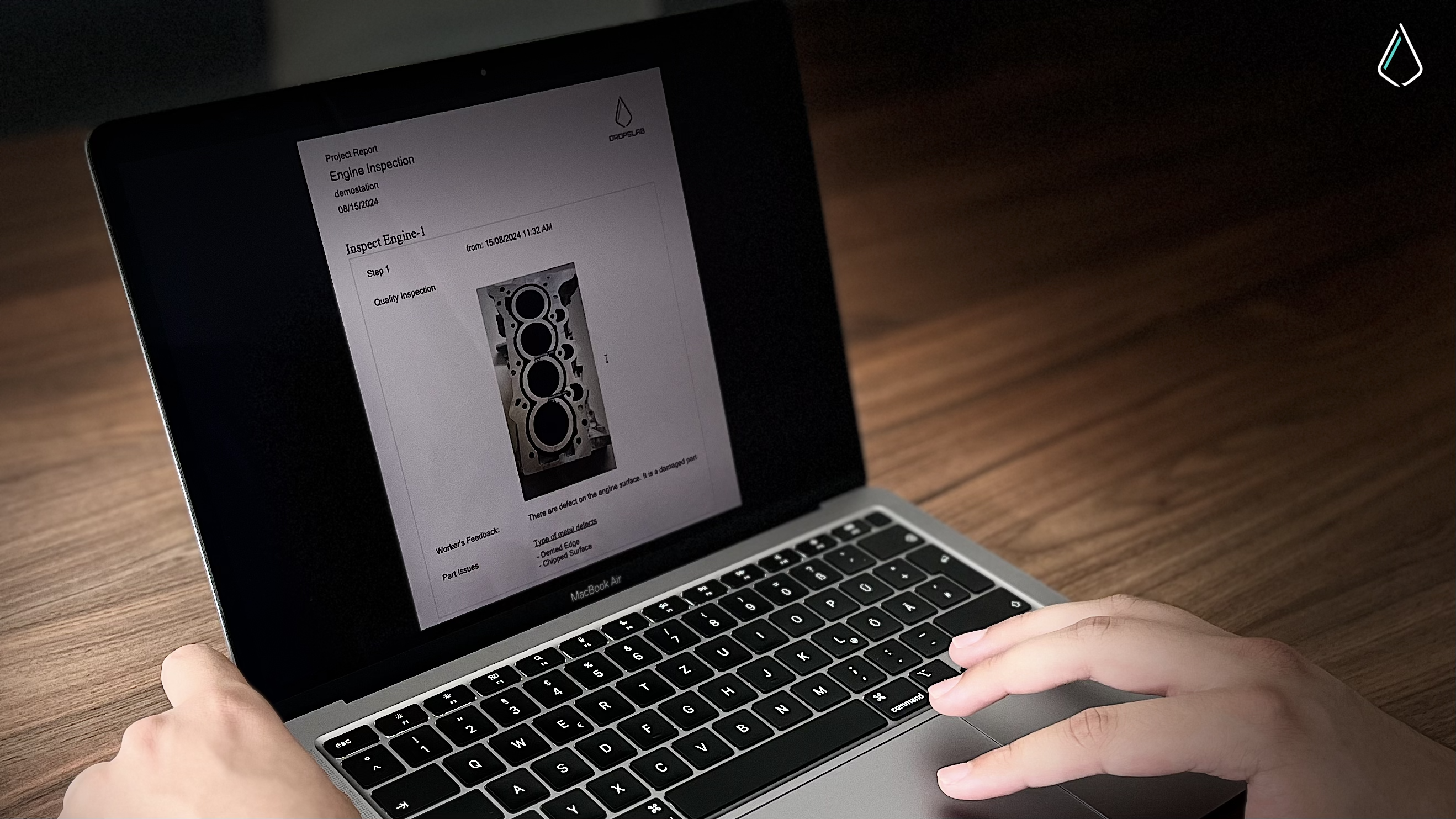

AI-powered predictive maintenance systems predict possible issues by evaluating information from sensors and equipment. It allows proactive maintenance and reduces downtime. AI-driven computer vision systems help quality control as they discover product flaws and make sure that standards are maintained, as well as improved. Artificial intelligence (AI) upgrades supply chain management by controlling inventories, forecasting demand variations, and spotting possible faults.

Robotic equipment and artificial intelligence (AI)

Robotic equipment and artificial intelligence (AI) are combined in intelligent automation to carry out activities that go beyond simple repetition, such as autonomous decision-making and condition adaptation. Using digital work instructions and immersive training experiences with virtual and augmented reality technologies, AI-driven training and support are revolutionising worker training.

| Did you know?

The World Economic Forum predicts that artificial intelligence will have an equally disruptive effect on manufacturing as the Industrial Revolution had in the 1950s. AI is perhaps one of the most revolutionary digital technologies. |

Enhanced Decision-Making and Strategic Planning

Moving forward in AI in manufacturing, we have how AI has a revolutionary effect on strategic planning and decision-making. Manufacturers may use data for in-the-moment analytics and data-driven decision-making by integrating AI technologies into their operations. With accurate data and predictive analytics, this data-driven strategy may assist operation managers and team leaders.

For example, supply chain optimisation, demand forecasting, and improved logistics management are all possible with the help of AI algorithms as it evaluates production data. This capacity lowers waste and boosts profitability by enabling enterprises to predict market trends, modify production schedules, and allocate resources effectively. AI will become more predictively accurate as it develops.

Workforce Transformation with AI in Manufacturing

This part will examine the three main ways that AI in manufacturing will affect the workforce: productivity, the skills that will be needed, and the necessity of efforts for upskilling and training. Let us go through each point below:

1. Productivity

Although some workers worry that AI will eventually replace them, collaborative work is likely to be the norm in the future. Human-robotic collaboration will improve shop floor flexibility, allowing for smooth production process modifications and higher overall output.

AI might take care of risky and monotonous jobs, freeing up workers to engage in more complex thinking and solving issues. This implies that workers will go from doing manual, repetitive jobs to doing more intricate problem-solving and decision-making.

2. Skill Shift

Manufacturers will have to spend time on retraining and upskilling their employees to close the skills gap to adjust to this change. To recognize patterns and reach well-informed conclusions, employees will, on the one hand, need to be able to comprehend data produced by AI systems. Conversely, however, the use and upkeep of AI-powered equipment and gadgets will require technical expertise. This emphasis on upskilling and reskilling will aid in bridging the skills gap that exists between present capabilities and industrial environments driven by AI.

3. Job Displacement

Incorporating AI technology into positions, encouraging human-AI collaboration, and generating new employment prospects like data scientists and AI specialists might all help allay worries about job loss.

Industrial AI enhances human talents by making problem-solving simpler, in contrast to worries about job replacement. To maintain product quality, operators have historically devoted several hours to process management and parameter optimization. AI control algorithms take care of regular changes, and recipes are perfected in a simulated environment before production. Operators may now supervise more extensive processes and concentrate on fixing strategic problems as opposed to tactical ones.

4. Training

The implementation of comprehensive training programs is imperative for manufacturers to prepare their personnel with the new abilities that AI will need. During this training phase, AI itself may be helpful. With performance data, skill matrices, and training report data, AI may tailor learning routes for individual employees. The programs can pinpoint areas of skill deficiency and provide customized, customized instruction.

To ensure that staff members keep current with industry practices and technological advancements, AI may also be used to continually evaluate performance data to detect skill gaps and offer specific training courses.

A workforce that is more skilled, flexible and ready to meet the needs of the AI-driven industrial environment is ensured by AI’s dual role in both developing and delivering the required training.

5. Competitive Edge

Worldwide competitiveness will be improved, and substantial economic development will be fueled by AI’s revolutionary effects on manufacturing. Gaining an advantage over their competitors is possible for businesses that invest in AI and successfully incorporate it into their industrial processes. Productivity gains, reduced production costs, and quick innovation are all results of this advantage.

Manufacturing businesses may beat rivals by using AI to produce customized goods more quickly, increase operational efficiency, and gain a competitive edge in the market.

AI in manufacturing is changing the game to gain an advantage, and it is not just about efficiency. Imagine manufacturing facilities that can produce customized goods on a large scale, react quickly to changes in the market, and anticipate equipment breakdowns before they occur. Manufacturers are empowered to do this using AI.

Artificial intelligence generates flexibility and adaptability that rivals lack by optimizing manufacturing lines, simplifying supply networks, and depending on data-driven decision-making.

Conclusion- The Future of AI in Manufacturing

Strategic planning is important for manufacturers if they want to completely benefit from AI. This includes creating an all-encompassing AI tactic that complements corporate objectives, creating the required infrastructure investments, and implementing an innovative culture.

The producers and data operators in charge of the AI projects should also continuously learn and change their strategies with the AI systems. They need to be one step ahead of technical developments so they can maintain their advantage over others and continuously review and improve AI initiatives.

FAQs

1. What is the role of AI in transforming manufacturing operations?

AI in manufacturing transforms operations by enabling predictive maintenance, optimising supply chains, and improving quality control through AI-powered computer vision systems. It also enhances decision-making with predictive analytics and automates routine tasks for efficiency and innovation.

2. How does AI impact the workforce in manufacturing?

AI impacts the workforce by improving productivity, shifting the skills needed toward data analysis and AI equipment maintenance, and opening up opportunities for upskilling. Although some jobs will be displaced, human-AI collaboration allows workers to concentrate on complex problem-solving and strategic tasks.

3. Can you provide examples of waste in lean manufacturing?

Manufacturers should align AI strategies with business objectives, invest in necessary infrastructure, and foster an innovative culture. Continuous learning, skill development, and refining AI initiatives are critical to staying ahead in the competitive landscape.

4. How does AI give manufacturers a competitive edge?

AI gives manufacturers a competitive edge through operational efficiency, lower production costs, and mass customisation. It helps manufacturers respond quickly to market changes, predict equipment failures, and streamline supply chains, driving innovation and market leadership.

5. What is the role of AI in workforce training and upskilling?

AI supports workforce training by identifying skill gaps, tailoring learning paths, and delivering customized training programs. It ensures employees are prepared for AI-driven environments by continuously assessing performance and providing targeted skill enhancement initiatives.