Introduction

Efficient inventory management is at the heart of a successful manufacturing facility. Without a proper system in place, businesses risk overstocking, understocking, and losing valuable time searching for items. Inventory management ensures you always know what you have in stock, where it is, and when you need to restock it.

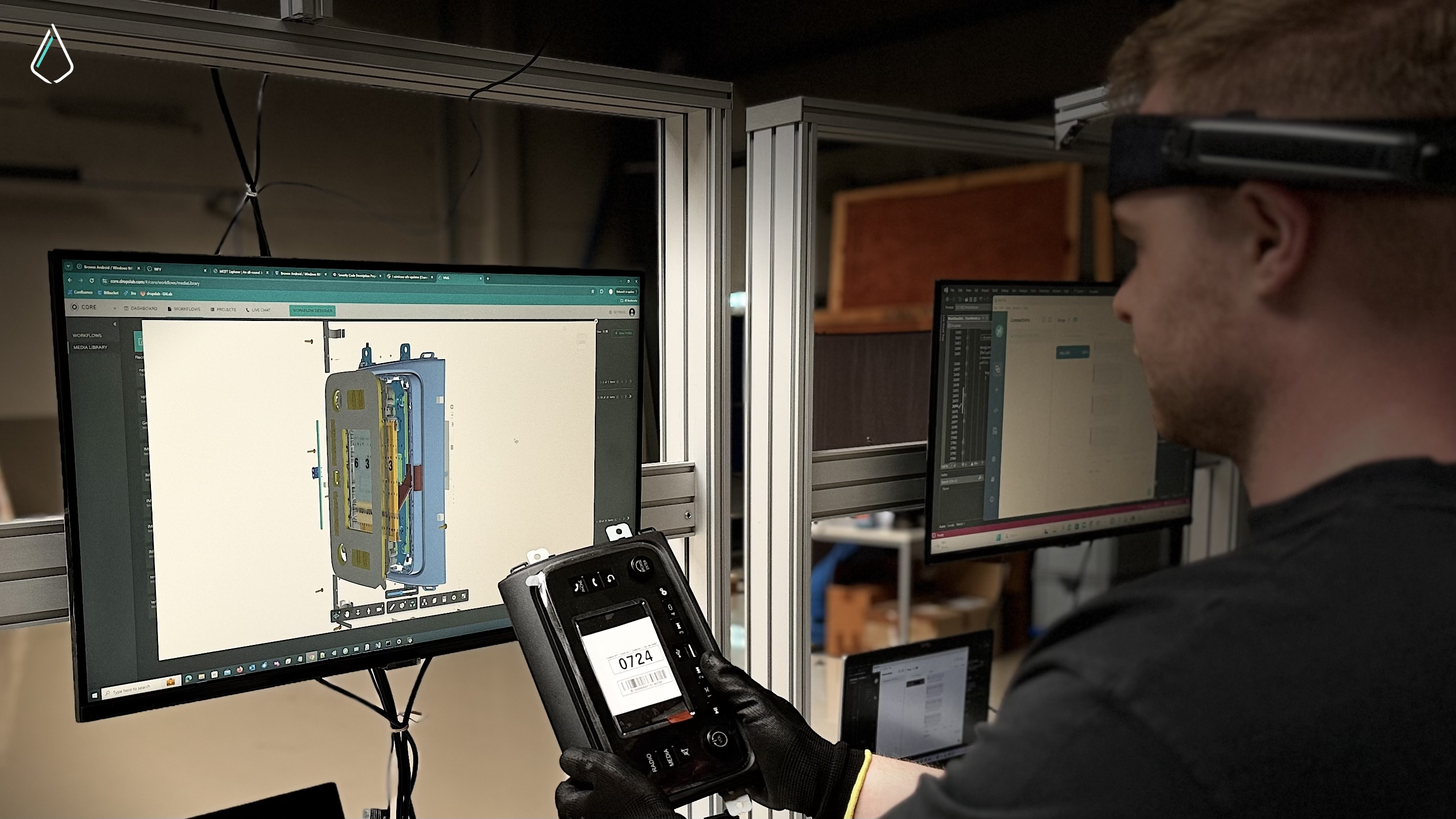

Advanced technologies have enabled inventory to evolve from manual processes to highly automated systems. Tech innovation companies offer innovative solutions that combine traditional inventory practices with cutting-edge tools, such as augmented reality (AR), to improve accuracy and efficiency.

In this guide, we shall explore the fundamentals of inventory management, its benefits, and how digital technologies can help you revolutionize your inventory practices.

What is Inventory Management?

It is the process of tracking, controlling, and overseeing the stock of goods in a business. This includes raw materials, components, and finished products. Effective inventory management ensures that businesses maintain optimal stock levels which are enough to meet customer demand without overstocking or tying up excess capital.

For instance, a manufacturing company may use inventory management to track raw materials for production, ensuring they have the right amount on hand without delays. Similarly, retailers rely on inventory management to keep their shelves stocked with products customers want.

Modern inventory management involves software tools that provide real-time updates, automate reordering, and integrate with other business systems. Dropslab Technologies takes this a step further by introducing AR-driven inventory tracking, making it easier for teams to locate and manage stock efficiently in large warehouses.

5 Reasons Why Inventory Management is Important?

Proper inventory management is critical for several reasons:

- Cost Control: Overstocking ties up capital and incurs storage costs, while understocking can result in lost sales and dissatisfied customers.

- Improved Efficiency: A well-organized inventory system saves time by reducing the effort spent searching for items.

- Accurate Forecasting: Businesses can use inventory data to predict demand patterns and adjust purchasing decisions accordingly.

- Customer Satisfaction: Ensuring the right products are available when needed helps maintain trust and loyalty among customers.

- Regulatory Compliance: Certain industries, such as healthcare and food, require precise tracking of inventory for safety and compliance purposes.

Key Components of Inventory Management

To understand inventory management better, let us break it down into its essential components:

1. Inventory Tracking

Tracking inventory is the backbone of inventory management. It involves knowing the exact location and quantity of each item in your stock. Dropslab Technologies leverages AR to enhance inventory tracking by providing warehouse workers with a real-time visual overlay of stock locations, making it easier to find items quickly.

2. Stock Levels

Maintaining optimal stock levels prevents overstocking and understocking. Businesses use techniques like minimum stock levels and safety stock to avoid disruptions in supply chains.

3. Inventory Turnover

Inventory turnover measures how often stock is sold and replaced over a period. High turnover indicates efficient inventory practices, while low turnover may signal overstocking or poor sales performance.

4. Inventory Categorization

Categorizing inventory using methods like ABC analysis (categorizing items based on their value) helps businesses prioritize resources. High-value items receive more attention, while low-value items are managed less frequently.

5. Technology Integration

Modern inventory systems integrate with enterprise resource planning (ERP) software and other tools to create a seamless flow of information. Dropslab Technologies’ AR-enabled solutions integrate easily with such systems, offering real-time data visualization and streamlined processes.

The Role of Technology in Inventory Management

Technology has transformed inventory management, allowing businesses to move away from error-prone manual processes to efficient automated systems. Key technologies include:

|

|

|

|

Dropslab for Inventory Management

Dropslab Technologies offers innovative inventory management solutions that seamlessly combine traditional practices with advanced technologies like augmented reality (AR). These solutions provide numerous benefits for businesses aiming to optimize their inventory processes. By utilizing real-time AR overlays, Dropslab enhances accuracy, eliminating human errors and visually displaying stock information for better decision-making. The technology also saves valuable time by simplifying the process of locating and handling inventory in large facilities, thereby improving overall efficiency.

With integrated AR and software systems, businesses gain better visibility into inventory levels and locations, ensuring they always have a clear picture of their stock. Additionally, Dropslab empowers employees with intuitive tools that streamline inventory tasks, boosting productivity and reducing operational delays. The solutions are designed to integrate easily with existing systems, providing a smooth transition to advanced management without disrupting current workflows.

Common Inventory Management Challenges

Even with the best tools, businesses can face challenges. Here are some common issues and how Dropslab Technologies can address them:

- Inaccurate Stock Counts: Manual processes often lead to discrepancies. Dropslab’s AR-driven solutions provide real-time updates, ensuring accuracy.

- Inefficient Processes: Searching for items in large warehouses wastes time. AR tools can guide workers directly to the desired items.

- Overstocking and Understocking: Without proper forecasting, businesses risk tying up capital or losing sales. Dropslab’s integrated systems provide predictive analytics to avoid such scenarios.

- Complex Operations: Managing inventory across multiple locations can be overwhelming. Dropslab’s centralized solutions simplify multi-site inventory management.

Summary

Inventory management is a critical aspect of running a successful business. By adopting modern tools and techniques, businesses can reduce costs, improve efficiency, and deliver better customer experiences. Dropslab Technologies is at the forefront of this transformation, offering advanced solutions that combine traditional inventory practices with cutting-edge technologies like AR. Whether you’re managing a small warehouse or a global supply chain, investing in innovative inventory management tools will set your business on the path to success.

FAQs

What is the difference between inventory management and inventory control?

Inventory management is a broader term that encompasses the entire process of tracking, ordering, and organizing stock. Inventory control, on the other hand, focuses specifically on regulating stock levels to prevent overstocking or understocking.

How can AR improve inventory management?

AR overlays real-time data onto physical spaces, helping workers quickly locate items and identify stock information. Dropslab Technologies uses AR to enhance efficiency and accuracy in warehouse operations.

What is the ideal inventory turnover ratio?

The ideal inventory turnover ratio varies by industry. For example, a grocery store might aim for a high turnover due to perishable goods, while a furniture store might have a lower turnover. Generally, a higher ratio indicates efficient inventory management.

How do I choose the right inventory management system?

Consider your business size, industry requirements, and integration needs. Look for systems that offer scalability, automation, and real-time updates. Dropslab Technologies provides flexible solutions that cater to businesses of all sizes.

Can small businesses benefit from advanced inventory management tools?

Absolutely! Small businesses can use tools like Dropslab’s AR-driven inventory management to save time, reduce errors, and compete with larger companies by optimizing their operations.