Introduction

The use of advanced technology in modern industries is reshaping workforce training and workforce safety. Computer Simulation Technology (computer simulation training) is a key driver in this change. But what exactly is computer simulation training, and how does it impact training and operational efficiency?

Computer Simulation Technology refers to the use of digital models to replicate real-world systems or environments. By leveraging mathematical models and computer algorithms, computer simulation training allows users to simulate scenarios, from simple mechanical functions to complex systems like industrial processes or medical procedures. These simulations offer users an interactive way to engage with realistic representations of tasks, systems, or environments.

The technology is used across various sectors, including aviation, manufacturing, healthcare, and defense. It creates a virtual environment where users can practice without the risk of real-world consequences. This technology can range from basic 2D models to immersive 3D simulations, explored through augmented reality.

Benefits of Computer Simulation Technology

The growing popularity of computer simulation training is due to its wide array of benefits, particularly in learning and development. Here are some most common benefits:

1. Risk-Free Training Environment

Computer simulation training allows employees to practice high-risk tasks in a controlled setting. This is crucial in industries like healthcare and aviation, where errors can lead to serious consequences. By simulating real-world scenarios, employees gain valuable experience without the associated risks.

2. Cost Efficiency

Utilizing computer simulation training significantly reduces training costs. By eliminating the need for physical materials and on-site equipment, organizations can save on expenses related to training venues and resources. Additionally, computer simulation training minimizes downtime in manufacturing environments, where machines might otherwise need to be taken offline for traditional training.

3. Accelerated Learning

One of the key advantages of computer simulation training is the provision of real-time feedback. Learners can instantly identify and correct mistakes, facilitating quicker skill acquisition. This immediate reinforcement helps shorten learning cycles and enhances overall comprehension.

4. Customized Training

Computer simulation training offers the flexibility to create tailored training experiences based on individual roles and skill levels. This customization increases engagement and ensures that training is relevant to each employee, leading to better knowledge retention.

5. Data Collection and Analysis

It enables detailed performance tracking during simulations, providing insights into areas of strength and improvement. Trainers can use this data to refine the learning process and enhance training effectiveness, ensuring continuous development of the workforce.

Improving Training with Computer Simulation Training

In sectors where precision and safety are vital, computer simulation training offers unparalleled advantages. For example, in healthcare, simulation allows doctors and nurses to practice complex surgical procedures or emergency response protocols without risking patient safety. In aviation, pilots can simulate in-flight emergencies to perfect their response without jeopardizing actual flights.

This ability to simulate high-risk or highly technical environments makes computer simulation training a perfect fit for training programs where hands-on experience is critical but difficult to arrange.

Computer Simulation Training in Manufacturing

Manufacturing is one of the industries that has greatly benefited from the integration of Computer Simulation Technology. By simulating production lines, machine operations, and material handling processes, computer simulation training enables manufacturers to optimize workflows, predict potential issues, and ensure quality control without disrupting actual operations. It allows engineers to virtually test and adjust equipment settings or manufacturing methods, reducing errors and improving the overall efficiency of the production cycle.

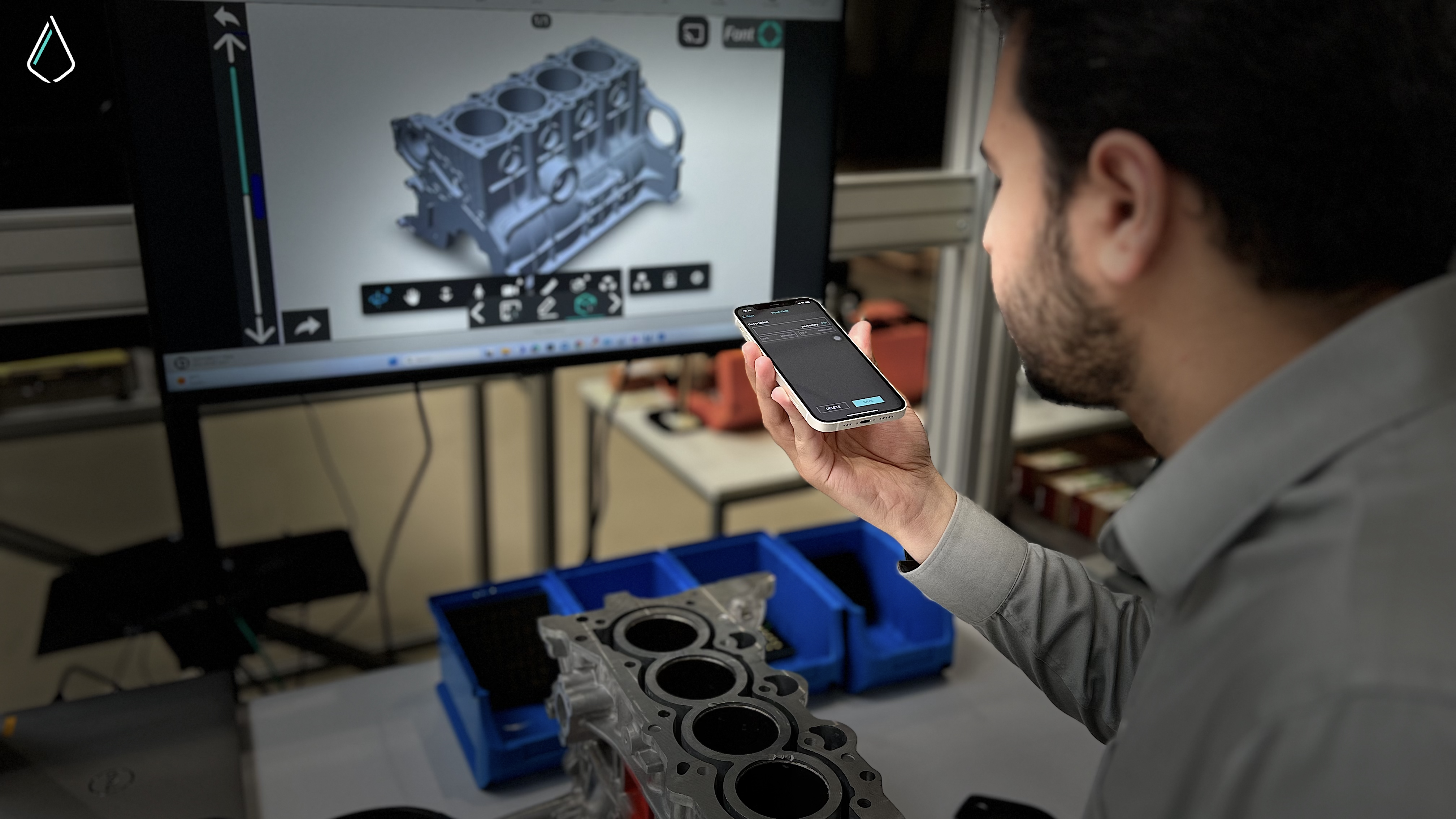

For example, in automotive manufacturing, computer simulation training can simulate the assembly of engine components, identifying areas where automation or manual adjustments may enhance efficiency. This approach ensures that new procedures or machines are tested in a virtual environment before being deployed, saving time and reducing costly errors.

Dropslab Technologies and Computer Simulation Training: A Perfect Match

While computer simulation training is impactful on its own, integrating it with innovative platforms like those provided by Dropslab Technologies takes training and workforce management to new heights.

Dropslab specializes in providing augmented reality (AR) and smart glasses platforms that enable workers to access hands-free contextual information and real-time support. Dropslab’s Workforce Management platform can seamlessly integrate computer simulation training to provide fully immersive, interactive training experiences. Imagine an employee using smart glasses to engage with a computer-simulated factory environment, where they can interact with machinery and perform tasks under real-time supervision, without ever being in harm’s way.

By combining it with AR capabilities, workers receive a more holistic, immersive training experience. For instance, smart glasses could overlay simulation-generated hazards in the worker’s physical environment, allowing them to respond in real time as if they were in an actual scenario. This enhances cognitive learning, bridging the gap between theoretical knowledge and real-world application.

With advancements in AI, AR, and machine learning, the future of training with computer simulation training looks even more promising. Dropslab focuses on continuous improvement and seamless integration of such cutting-edge technologies means that companies can expect to see more interactive, data-driven training solutions in the coming years.

By leveraging the power of computer simulation training and the smart solutions provided by Dropslab , industries will not only enhance their training protocols but also cultivate a more competent, safety-conscious workforce. This combination sets a new standard for workforce training, ensuring that employees are better equipped to handle challenges while reducing the risks and costs associated with real-world training.

Summary

Computer Simulation Technology is revolutionizing training across various industries, including manufacturing, by providing a risk-free, cost-effective, and customizable environment for skill development and process optimization. computer simulation training enhances learning and operational efficiency through real-time feedback and data analysis, allowing employees to practice complex tasks and manufacturers to simulate production processes safely. Integrating it with innovative platforms, such as augmented reality solutions by Dropslab , creates immersive training experiences that bridge theoretical knowledge, practical tasks, and manufacturing workflows. This combination not only improves workforce competency and productivity but also ensures safety and efficiency in high-stakes environments, setting a new standard for training and manufacturing in modern industries.

1. What is Computer Simulation Training?

Computer Simulation Training is a process of mimicking or simulating real-world systems or environments using digital models. It enables the users to perform in realistic scenarios, but in a risk-free and controlled virtual setting.

2. Which industries benefit most from Computer Simulation Training?

Manufacturing, healthcare, aviation, and defense industries are on top of the list, ranging from simulating production lines in factories to practicing complex surgical procedures or emergency flight scenarios.

3. What are the key advantages of Computer Simulation Training?

Some of the key benefits include:

- A risk-free environment for practicing high-stakes tasks.

- Cost saving through the avoidance of physical resources and downtime.

- Fast learning due to real-time feedback. – Training tailored to the role and skill level of the individual.

- Monitoring of performance with data-driven insights for continuous improvement.

4. What are the advantages of Computer Simulation Training in manufacturing?

In manufacturing, it optimises workflows, test equipment settings virtually, and predict issues without disrupting operations. It enables the workforce to upgrade their skills in simulated environments so that the task has reduced error in a real scenario.

5. How does Dropslab Technologies enhance Computer Simulation Training?

Dropslab Technologies combines Computer Simulation Training with augmented reality (AR) and smart glasses. It can provide hands-free guidance, real-time supervision, and performance tracking for continuous improvement in manufacturing and other industries, making training highly immersive and interactive.