Introduction to Manufacturing SOPs

Global manufacturing scenario is more dynamic than ever, and it is heavily marked by digital transformation. For companies to stay in the loop and reap maximum benefits, digital adaptation is a prerequisite. In this regard, SOPs is an important area to upgrade. Therefore, in this blog, we shall explore manufacturing SOPs.

Manufacturing standard operating procedures (SOPs) ensure that workflows are efficient, and clear to follow. These procedures are detailed, written guidelines that record all relevant processes and steps.

The benefit? They guide frontline workers through various tasks, ensuring consistent, high-quality production aligned with regulatory standards. These manufacturing SOPs ensure that teams can confidently follow recurrent processes, reducing room for human error.

Please Note- Before we proceed further, please note this blog is not an academic piece on manufacturing SOPs. It is for only informational purposes. Hence, we suggest not to cite it as an academic source.

Standard Operating Procedures in Modern Manufacturing

The rise of advanced technologies like IoT, artificial intelligence, and augmented reality has made manufacturing more sophisticated. Traditionally, these SOPs were just a piece of paper, but now they have become digital work instructions.

You would be glad to know that Dropslab Technologies plays a vital role here with its innovative tools, created to make SOPs interactive and efficient.

These Manufacturing SOPs are essential in today’s manufacturing environment as they improve consistency by recording each task and ensuring that each team member follows the same standards, reducing variability and maintaining quality. They enhance training as they serve as a guideline for new employees, and since the performing manufacturing operation standards outline the safety measures, they help minimize risks and keep workers protected. Many industries have strict regulatory compliance for their manufacturing processes, and these standards help them meet their requirements and avoid penalties and costly fines.

Critical Components of SOPs

Creating impactful SOPs involves more than just listing steps. Effective SOPs are clear, concise, and easy to follow. Here are the essential components:

There should be a purpose that describes why the SOP exists, detailing the goals it intends to achieve. A scope to specify the boundaries and extent of the SOP, defining who it applies to and under what circumstances. List the personnel accountable for specific tasks, from operators to supervisors. Break down the exact steps required to complete the task, often including diagrams or media to clarify complex tasks. Describe any checks or quality assurance measures involved in the process and outline safety requirements to prevent accidents and injuries during the task.

How Dropslab Approaches SOPs?

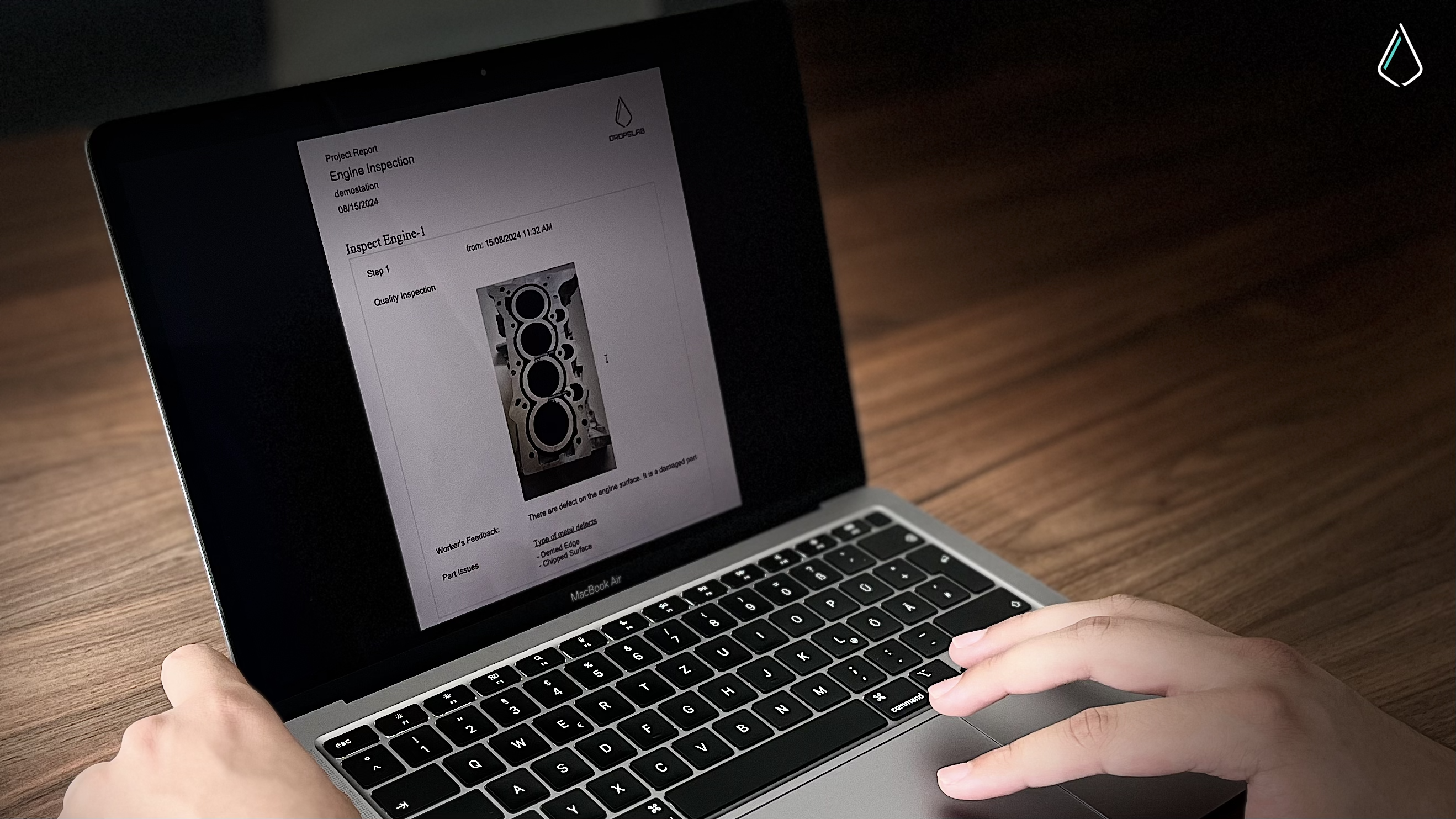

Dropslab supports manufacturing SOPs with its unique digital solutions, making SOPs more interactive and accessible for workers at every level. Our AR-based solutions and digital instructions help frontline workers access SOPs hands-free right when they need them. Below mentioned are some more points in this regard:

1. Real-Time Guidance with AR

Using augmented reality, Dropslab systems display instructions directly in a worker’s field of view, reducing downtime and enhancing focus. With real-time guidance, team members can perform tasks accurately and confidently, even for complex workflows.

2. Adaptive Learning Modules

To help employees retain information and improve over time, Dropslab’s learning modules adapt to each user’s needs. Our platform tracks progress and suggests relevant manufacturing SOPs based on previous tasks, enhancing training effectiveness.

3. Instant Updates and Compliance

Compliance and regulations evolve frequently in rapidly changing industries. The Dropslab platform allows supervisors to update SOPs instantly, ensuring all staff members can access the latest instructions and requirements. With centralized control, we help manufacturers stay ahead of regulatory changes without disrupting the workflow.

Implementing SOPs with Dropslab: A Step-by-Step Guide

Here’s a simple overview of how manufacturers can start using Dropslab solutions to transform their SOP management:

They can assess their current SOPs by evaluating the existing SOPs. Identify areas where digital tools could improve clarity, accessibility, or compliance. Then, use Dropslab’s platform to create digital versions of the SOPs, adding multimedia elements such as videos or AR instructions for enhanced understanding.

Create interactive training modules to align with your SOPs, allowing new hires to learn faster and retain information effectively. Equip workers with AR-enabled devices, giving them hands-free access to SOPs and real-time guidance for each task. Utilize data analytics to monitor SOP adherence, identifying bottlenecks or areas for improvement.

As technology advances, SOPs will continue to evolve, becoming more intelligent, adaptable, and data driven. Dropslab remains committed to helping manufacturers adapt to these changes, enabling more intelligent workflows, safer workplaces, and more resilient operations.

Summary

Manufacturing SOPs guidelines but it also go beyond. The SOPs are essential for quality control and workforce safety. At Dropslab, we empower manufacturers to optimize their SOPs, integrating digital tools and AR to create a simple, hands-free experience. With Dropslab, your SOPs can go beyond static documents and become a dynamic part of daily operations, ensuring excellence and consistency at every step.

Ready to experience the difference?

If you have any questions, feel free to contact our team.

FAQs

1. What are manufacturing SOPs, and why are they important?

Manufacturing SOPs are detailed, written guidelines outlining every step of a process to ensure consistent, high-quality production. They help reduce errors, improve efficiency, enhance training, and ensure compliance with regulatory standards.

2.How have manufacturing SOPs evolved with modern technology?

Paper-based SOPs have evolved into digital SOPs, with the integration of advanced technologies such as IoT, AI, and AR. This evolution makes SOPs more interactive, accessible, and effective in the current manufacturing environment.

3. What are the components that make an SOP effective?

Good SOPs have a definite purpose, scope, accountability assignments, step-by-step detailed instructions, checks for quality assurance, safety measures, and other supporting elements like diagrams or videos for clarity.

4. How does Dropslab Technologies enhance SOP management?

Dropslab develops digital solutions offering real-time, AR-based guidelines, modules for adaptive learning to individualize training, and even instant updates toward compliance. These tools provide flexibility in handling SOPs, leading to increased productivity and safety.

5. What are the steps to implement SOP solutions with Dropslab?

Implementation involves reviewing existing SOPs, creating digital versions with multimedia content, aligning the training modules, providing the workers with AR-enabled devices, and using analytics to monitor adherence and improve processes.