Introduction

AI can help companies improve their existing manufacturing processes, but supply chain leaders must also understand the potential challenges of using AI in manufacturing. Algorithms, automation, and machine learning (ML) can potentially help organizations reduce operational costs, increase efficiency, and improve product quality. However, integrating AI with other systems and finding employees with the required AI expertise might be difficult. Some manufacturers might find integrating AI into existing operations to be a complex process. In this short article, we shall explore the challenges of AI in manufacturing and look at the possible solutions. Keep reading!

How AI Can Help Improve Manufacturing

Companies can use AI in manufacturing to do the following:

| Model and test different use cases, which can lead to manufacturing improvements. | Identify any factors that are harming productivity and find areas to improve. |

| Improve manufacturing speed and quality through automation. | Spot areas of repair. |

5 Challenges of Using AI in Manufacturing

Using AI in manufacturing can also lead to potential problems. Supply chain leaders should be aware of these issues and take precautions against them. Let us see what these challenges are and how it can be resolved:

1. Poor data quality

AI and ML rely on access to large quantities of high-quality data, so their outputs will be unreliable if the company’s data includes low-quality information.

To avoid data quality issues, consider the following approaches for AI in manufacturing:

- Understand what data the algorithm needs and how the algorithm is processing data.

- Collect, collate, and cleanse the needed information.

- Regularly audit inputs and outputs.

2. Employee job security concerns

Many people are currently concerned about how AI in manufacturing will affect their livelihoods. Workers who think AI in manufacturing will take away their jobs had a 27% lower intent to stay at their company, according to a 2023 Gartner survey.

Company leaders should understand the workforce’s concerns about being replaced. Employees might not wish to engage with the company’s AI technology, which can potentially lead to delays. Supply chain leaders should work with other leaders at their company to prepare for these issues by being straightforward and honest about AI’s potential effects on the organization and offering reskilling and training opportunities for any affected workers.

3. Limited access to talent

Implementing AI and ML requires specific knowledge, and manufacturing companies will need to invest in data scientists, analysts, and other algorithm and automation experts. However, the rapid growth of AI across industries can make it difficult to find people with the right expertise to fill these roles.

A similar issue can affect an organization’s existing manufacturing workforce, as the employees might not possess the proper knowledge and skills. Company leaders can resolve these issues by moving forward with the following:

- Understand recruiting needs by collaborating with the HR department, labor force experts, and potential vendors to learn about the talent needs for implementing and running AI.

- Invest in competitive compensation and packages to attract the most talented AI experts.

- Ensure employees have access to ongoing support when using new AI capabilities.

4. Lack of system integration

AI manufacturing systems must integrate with other tech to improve manufacturing processes. Legacy systems are common in manufacturing companies for many reasons, including unclear ROI for upgrades and the overhead of implementing newer tech. Still, AI in manufacturing might not be able to integrate with older systems.

Manufacturing companies looking to integrate AI with the organization’s current tech should take the following action:

- Review the areas within the organization with which the AI-powered manufacturing systems must integrate.

- Talk to AI vendors about the tech’s integration capabilities.

- Learn about any needed upgrades to existing manufacturing systems to enable AI.

5. Trying to do too much too quickly

Many manufacturers are eager to implement AI in manufacturing quickly, only to take advantage of potential benefits and improve the organization’s competitive advantage. Unfortunately, doing too much too soon can result in a poor implementation that doesn’t deliver ideal results.

Company leaders can avoid this by taking a phased approach to AI implementation and doing the following:

- Focus on one specific manufacturing process to improve.

- Research AI software that can optimize that process and enable the company to improve capabilities later.

- Put a limited AI tool in place to track how well the implementation functions.

- Optimize that AI process and note any lessons learned.

- Use a similar approach to gradually introduce AI across all company areas in which it can make a difference.

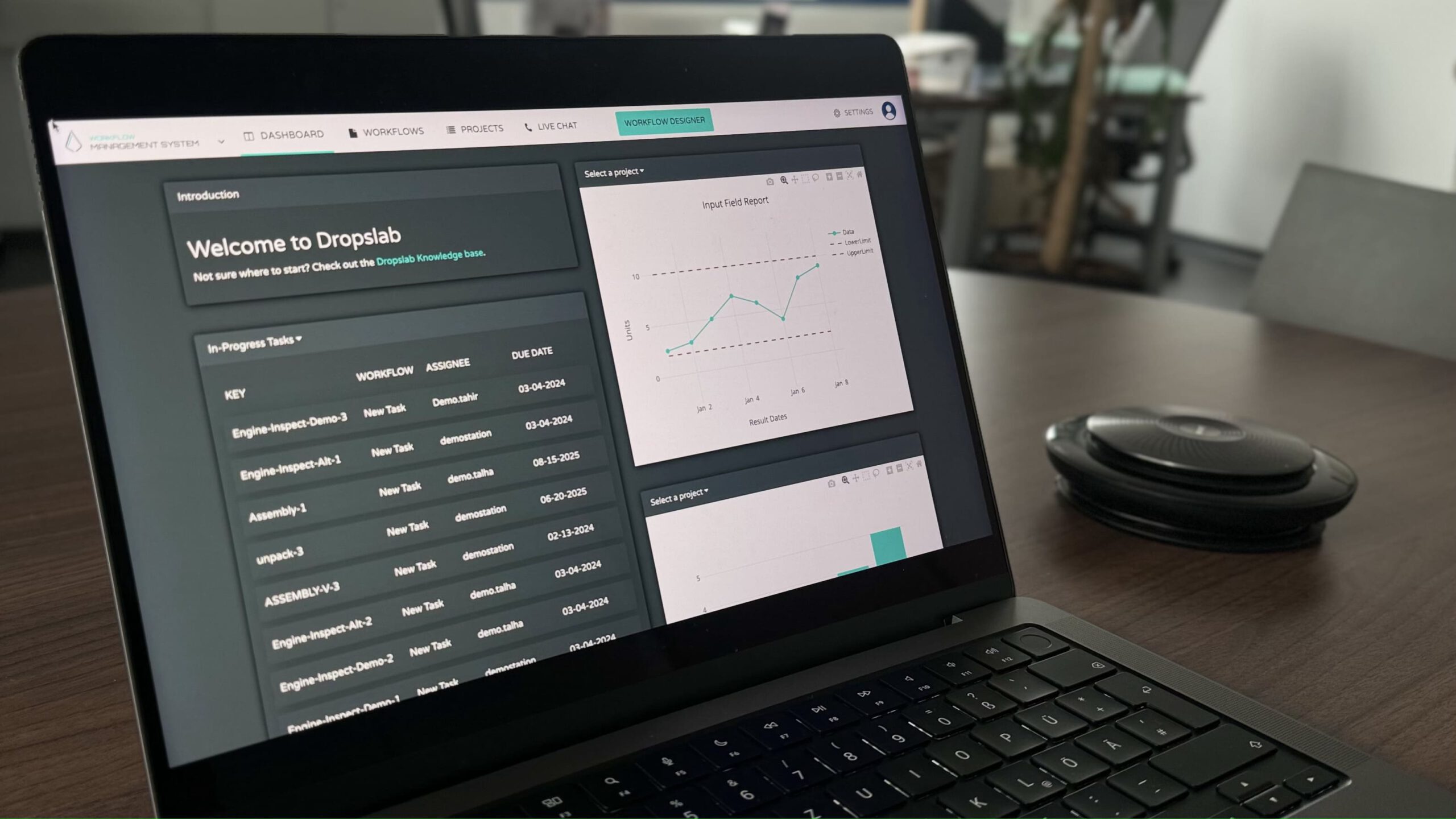

For more on such topics, stay tuned to updates from Dropslab, here on the website and LinkedIn.

FAQs

Here are some commonly asked questions regarding AI in manufacturing:

How can AI improve manufacturing processes?

AI has the ability to optimize manufacturing by modeling and testing different scenarios, identifying productivity issues, enhancing automation, and improving speed and quality. It can also detect areas requiring repairs, leading to reduced operational costs and increased efficiency.

What are the key challenges of using AI in manufacturing?

Some challenges include:

- Poor data quality

- Employee concerns about job security

- Limited access to AI talent

- Lack of system integration with legacy technologies

- Risks of implementing AI too quickly without proper planning.

How can companies address employee concerns about AI adoption?

Companies should openly communicate AI’s role, provide reskilling and training opportunities, and emphasize AI as a tool for collaboration rather than replacement. Building trust and offering transparent plans can help alleviate fears.

What steps can be taken to ensure successful AI integration with existing systems?

Organizations should review their legacy systems, discuss integration capabilities with AI vendors, and plan for necessary upgrades. Collaboration with IT teams and phased implementation are crucial for seamless integration.

What should manufacturers consider before implementing AI solutions?

Manufacturers should start with specific processes, research the best AI tools for those needs, and adopt a phased approach to test and optimize implementations. Building a strong foundation ensures long-term success and scalability.