Introduction

Imagine a busy factory floor, where machines are running, and workers are performing multiple tasks in a race against the clock. In such high-pressure environments, human workers are often pushed to their limits, especially when working alongside robots that demand precision and speed. Errors, fatigue, and inefficiencies can quickly pile up, costing both time and money. But here is the challenge: while automation and robotics promise efficiency, they cannot always account for the adaptability and problem-solving skills of humans.

This is where human factor engineering (HFE) comes into play. As industries push for more smooth integration between humans and machines, the need for designing systems that optimize human capabilities is greater than ever. Human factors engineering makes sure that these systems accommodate human strengths while minimizing weaknesses, ensuring safer, more efficient workflows.

What is Human Factor Engineering?

Human Factor Engineering (human factor engineering), also known as ergonomics or human-centered design, is the study of designing systems, machines, and tools that improve the interaction between humans and their working environments. human factor engineering focuses on optimizing how people interact with technology, ensuring that devices, processes, and work environments are designed around human capabilities and limitations.

By integrating ergonomic principles, cognitive science, and psychology, human factor engineering aims to minimize errors, reduce fatigue, enhance safety, and boost productivity, particularly in complex and demanding environments such as manufacturing. Some key areas where human factor engineering can improve human-machine interaction include:

- Ergonomic design: Ensuring tools and workstations are designed to reduce physical strain on workers.

- Cognitive load management: Simplifying information flow so workers can make quick, accurate decisions without feeling overwhelmed.

- User-friendly interfaces: Designing machines and software with intuitive controls that are easy to learn and operate.

- Training and skill adaptation: Providing workers with the skills and training necessary to work effectively alongside machines, without pushing them to their limits.

High Costs of Robotics: The Need for Cobots

Industrial robots, while highly efficient in performing repetitive and precise tasks, often come with significant costs. The upfront investment in these machines, combined with the maintenance and technical training required to operate them, can be prohibitive for many small- and medium-sized businesses. Moreover, traditional robots are designed to operate independently and are usually segregated from human workers for safety reasons, limiting their flexibility.

While, cobots are designed to work alongside humans, complementing their capabilities and reducing physical and cognitive strain. They bridge the gap between human workers and fully automated machines, providing the best of both worlds: the precision of robotics and the adaptability of human skills. Cobots are equipped with sensors and safety features that allow them to detect and respond to human presence. This makes it possible for cobots to collaborate safely with humans in shared workspaces, performing tasks such as lifting heavy objects, assembling products, or assisting with repetitive motions.

Additionally, cobots are more affordable than their fully automated counterparts. Their versatility and ease of programming make them a cost-effective solution for companies looking to improve production without committing to full-scale automation. Cobots can be deployed quickly, programmed with minimal effort, and adapted to various tasks; whether it’s in automotive assembly lines, electronics manufacturing, or even in small-scale industries.

4 Ways Human Factor Engineering Improves Collaborative Robotics

While cobots represent a significant step toward more human-friendly automation, they still rely on well-designed interactions between humans and machines to maximize their potential. Human Factor Engineering plays a critical role in ensuring these interactions are safe, efficient, and productive.

Here’s how human factor engineering improves collaborative robotics:

1. Enhancing Safety in Human-Machine Collaboration

Safety is a top priority in environments where humans and machines work side by side. human factor engineering ensures that cobots are designed to work at appropriate speeds and with adequate safeguards to prevent accidents. Sensors, motion control algorithms, and ergonomic designs allow cobots to stop immediately if a human is too close, preventing injuries.

2. Reducing Physical and Mental Strain on Workers

One of the key goals of human factor engineering is to minimize the physical and mental stress on human workers. Cobots are often deployed for tasks that are physically demanding or repetitive, such as heavy lifting or monotonous assembly work. By offloading these tasks to robots, human workers can focus on more complex tasks that require problem-solving and creativity.

3. Simplifying Cobot Operation for Seamless Integration

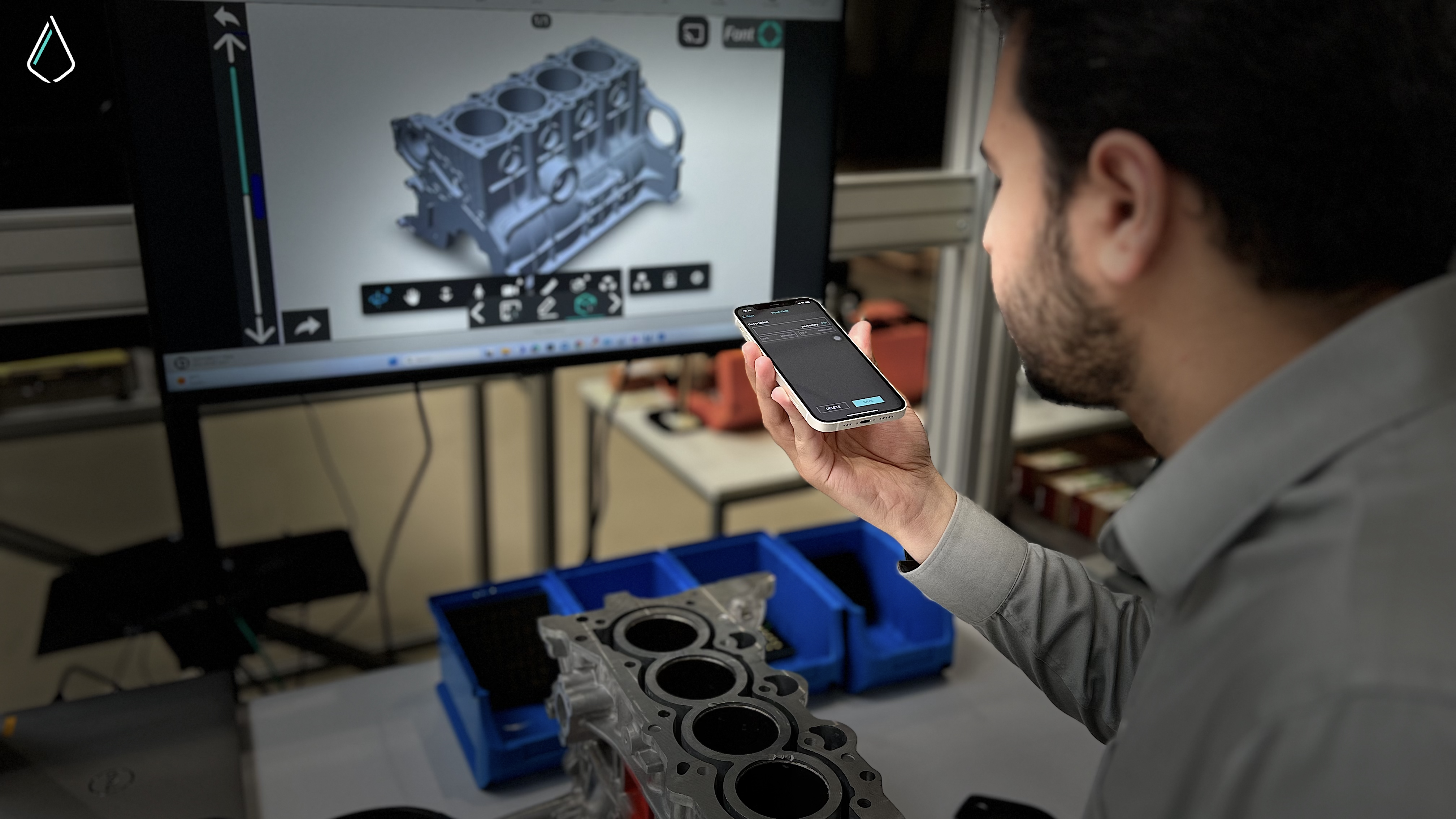

Cobots are designed to be easy to operate, but human factor engineering takes this further by simplifying interfaces and controls so that workers can operate them with minimal training. This includes developing user-friendly programming interfaces, intuitive dashboards, and optimized maintenance processes.

4. Boosting Efficiency and Productivity with Worker-Centered Design

By designing systems that align with human cognitive and physical abilities, human factor engineering ensures that workers can work efficiently and effectively alongside cobots. This leads to fewer errors, less downtime, and higher overall productivity.

Real-World Applications of Human Factor Engineering in Cobots

Several industries have already begun to see the benefits of applying Human Factor Engineering to collaborative robotics. For example, in assembly lines, cobots assist with tasks like tightening bolts or painting car parts. Human factory engineering ensures that these robots are integrated into the workflow in a way that minimizes disruption and enhances human workers’ ability to oversee and manage the production line.

Similarly, in hospitals, cobots are used to assist nurses and doctors with tasks like handling medical supplies or even aiding in surgery. The ergonomic design of these robots, combined with human factor engineering principles, ensures that medical professionals can focus on patient care while the robots handle routine tasks. Cobots are increasingly used in logistics to help with packaging, sorting, and transporting goods. human factor engineering ensures that these robots are integrated into the workforce in a way that reduces the strain on human workers and optimizes the workflow.

Future of Human Factor Engineering in Collaborative Robotics

As technology continues to evolve, so too will the relationship between humans and machines. The future of human factor engineering in collaborative robotics looks promising, with advancements in artificial intelligence (AI), machine learning, and cognitive computing. These technologies will enable robots to better understand human intentions, preferences, and limitations, allowing for even more seamless collaboration.

In the near future, we can expect robots that learn from human behavior in real time, adjust their actions accordingly, and provide real-time feedback to optimize workflows. These systems will not only improve efficiency but also enhance job satisfaction for human workers by allowing them to focus on creative and intellectually stimulating tasks.

Conclusion

Human Factor Engineering is critical to optimizing the way humans interact with collaborative robots. By designing systems that complement human abilities, human factor engineering ensures that human-machine collaboration is safe, efficient, and productive. As the cost of full automation remains high, cobots offer a practical solution for companies looking to enhance their production capabilities without sacrificing flexibility. With companies like Dropslab leading the way, the future of human factor engineering in collaborative robotics looks bright, promising safer, smarter, and more effective work environments.

FAQS

1. What is Human Factor Engineering (HFE), and why is it important in collaborative robotics?

Human Factor Engineering focuses on designing systems that optimize interactions between humans and machines. In collaborative robotics, HFE ensures safe, efficient, and productive collaboration by aligning cobot design with human capabilities and limitations.

2. How do cobots differ from traditional industrial robots?

Unlike traditional robots, which operate independently and are often segregated for safety, cobots are designed to work alongside humans. They feature sensors, safety mechanisms, and user-friendly programming, making them adaptable, affordable, and safer for shared workspaces.

3. What role does HFE play in reducing worker strain in industries?

HFE minimizes physical and mental strain by designing ergonomic systems and delegating repetitive or physically demanding tasks to cobots. This allows human workers to focus on tasks requiring creativity and problem-solving skills.