Introduction

In the manufacturing industry, “objective evidence” ensures efficiency, safety, and continuous improvement. But what does objective evidence mean? Simply, it refers to qualitative or quantitative proof that a specific action or event occurred, often documented to validate compliance with standards or verify process outcomes.

Examples include timestamped photos, sensor data, inspection reports, and records of training sessions. Collecting such evidence has become indispensable in today’s era of digital transformation. By leveraging advanced tools and technologies, manufacturers can streamline operations, mitigate risks, and foster a culture of accountability.

This article delves into the importance of collecting objective evidence on the factory floor, explores its applications, and explains how digital solutions enhance this process.

What Is Objective Evidence?

It is verifiable information that proves an activity, process, or outcome was completed. Unlike subjective judgments, objective evidence relies on concrete data that can be independently validated. For example, a timestamped photograph of a completed Lockout/Tagout procedure serves as objective evidence of compliance with safety protocols. This type of evidence is essential for ensuring processes are followed accurately, and it provides valuable insights for continuous improvement in manufacturing operations.

Why Collect Objective Evidence on the Factory Floor?

For manufacturing executives leading digital transformation initiatives, it is a vital component of effective operations. Here’s why:

-

Identify Problems Early

It can reveal inefficiencies or problems within factory operations. For instance, recurring machine breakdowns or inconsistencies in product quality often have underlying causes that can be identified through data collection. By analyzing evidence such as maintenance logs, defect rates, or process runtime data, manufacturers can pinpoint issues and implement corrective actions before they escalate.

-

Track Progress Over Time

Tracking progress is another significant benefit. Whether you’re focusing on improving safety, reducing downtime, or enhancing productivity, having reliable data allows you to measure the effectiveness of your initiatives. For example, if you’re working to reduce workplace accidents, collecting data on near-misses and safety incidents over time can help demonstrate tangible improvements.

-

Enhance Employee Safety

Factories often involve hazardous environments with heavy machinery, chemicals, and other risks. Things such as safety inspection records and incident reports, plays a crucial role in ensuring compliance with safety regulations and identifying areas that need improvement. By continuously monitoring and documenting safety practices, manufacturers can create a safer workplace and prevent costly accidents.

-

Ensure Regulatory Compliance

Industries are increasingly governed by stringent regulations that require proof of compliance. Objective evidence provides manufacturers with the necessary documentation to demonstrate adherence to quality and safety standards during audits or inspections.

-

Support Data-Driven Decision Making

It forms the foundation for informed decision-making. When process improvements or changes are based on reliable data rather than assumptions, manufacturers can achieve better outcomes and optimize their resources effectively.

Dropslab & Objective Evidence

Dropslab Technologies provides innovative solutions that streamline the collection, analysis, and utilization of objective evidence on the factory floor. By using advanced tools such as IoT sensors, blockchain technology, and digital forms, Dropslab ensures transparency, accountability, and traceability across operations. Dropslab offers several key features that make collecting and utilizing objective evidence seamless.

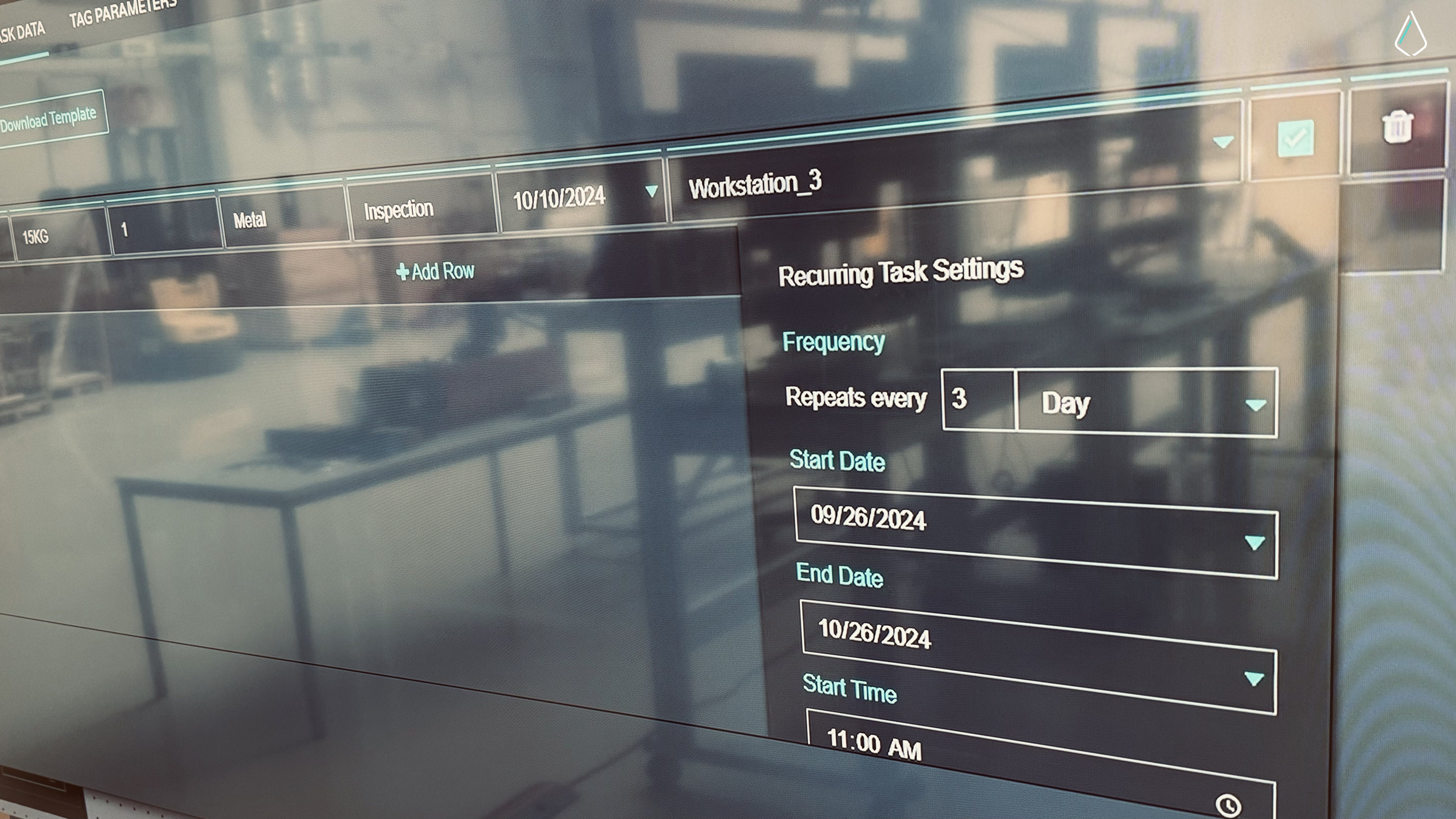

Their digitized procedures transform manual processes into digital workflows, enabling manufacturers to document every step of their operations with ease. Integrated data capture allows forms, photos, and sensor data to be incorporated directly into procedures, ensuring that objective evidence is collected effortlessly. Real-time reporting capabilities enable manufacturers to monitor progress and generate detailed reports that support informed decision-making.

Blockchain-backed traceability ensures the authenticity and integrity of collected data, providing an added layer of security and trust. Additionally, Dropslab’s scalable solutions cater to businesses of all sizes, whether managing a single factory or a global operation, making their tools adaptable to diverse manufacturing needs. By integrating Dropslab’s solutions into your operations, you can ensure that objective evidence is captured accurately, analyzed effectively, and utilized to drive meaningful improvements.

Conclusion

Understanding the meaning and significance of objective evidence is essential for modern manufacturing operations. It serves as a cornerstone for ensuring safety, compliance, and continuous improvement. By collecting and analyzing objective evidence, manufacturers can identify inefficiencies, track progress, and foster a culture of accountability. With solutions like Dropslab Technologies, the process of gathering and utilizing objective evidence becomes effortless. By digitizing workflows and leveraging advanced technologies, manufacturers can achieve greater transparency and efficiency while staying ahead in a competitive industry.

FAQs

1. What does "objective evidence" mean in manufacturing?

Objective evidence refers to tangible, verifiable proof that a specific action, process, or outcome has occurred. It can include photos, logs, sensor data, or inspection reports that confirm compliance with procedures, safety standards, or quality requirements.

2. Why is objective evidence important on the factory floor?

Objective evidence is crucial for identifying problems, tracking progress, ensuring safety, maintaining compliance, and supporting data-driven decision-making. It provides the necessary transparency and accountability to improve processes and meet regulatory standards.

3. How can digital tools help with objective evidence collection?

Digital tools, such as those offered by Dropslab Technologies, simplify the process of collecting, storing, and analyzing the evidence. They enable manufacturers to digitize workflows, automate data capture, and access real-time insights for continuous improvement.

4. Can objective evidence improve workplace safety?

Yes, objective evidence plays a critical role in improving workplace safety. By documenting near-misses, incidents, and safety inspections, manufacturers can identify high-risk areas and implement measures to prevent accidents.