Dropslab Technologies Driving Digital Change with RealWear Solutions

We have explored the power of using and creating efficient workflows in our article. Now, learn about the innovative tool designed to assist and empower frontline workers. In today’s industrial setting; safety, efficiency, and precision are crucial. There are many tools being used to achieve these goals and one of them is RealWear which is designed to change the way industrial workers perform their tasks.

At Dropslab Technologies, we know the importance of hands-free work with accurate digital instructions. Currently, we have successfully uploaded our application on the RealWear store and we use it to improve compliance in industries. Let’s learn more about RealWear and how it is beneficial for Dropslab below.

RealWear: The Future of Hands-Free Industrial Innovation

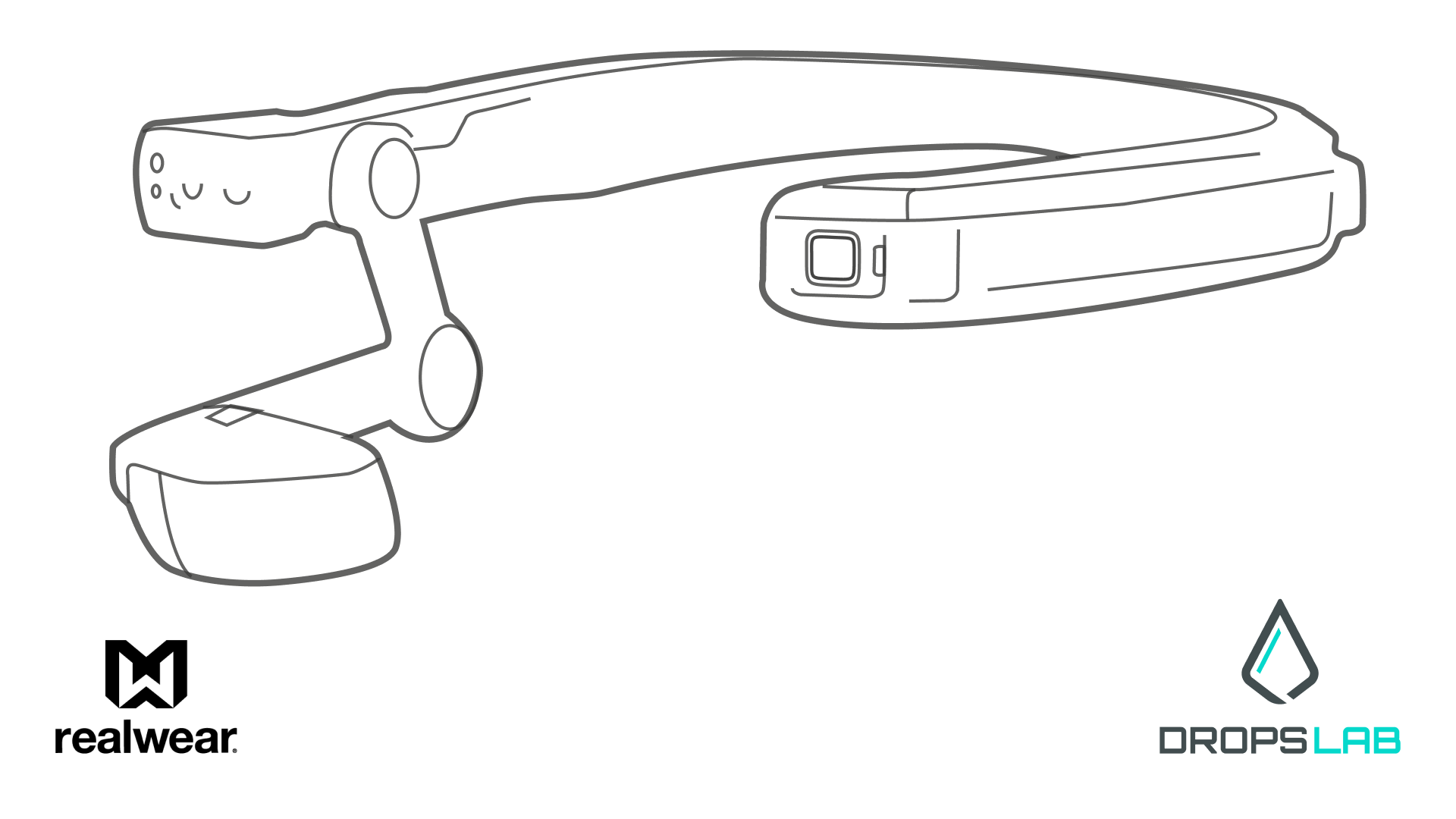

RealWear is a modern hands-free smart glasses technology. These smart glasses are AI voice-powered built to enhance productivity, efficiency, and safety of workforces throughout multiple industries. This augmented reality enabled wearable device are created for demanding factory shop floors which makes picking, sorting, and navigation easy. It lets frontline workers perform tasks requiring full focus without the hassle of going back and forth between the workstations and paper-based manuals. Below, are the key features which helps with the industrial productivity.

Key Features of RealWear

- These devices come with voice command feature which lets workers to navigate applications, capture data and access documents using easy and simple voice commands.

- The high-resolution camera of RealWear is useful for remote inspections, reporting and troubleshooting. It provides a clear visual record of the work being done on the workstations/shop floor.

- Its rugged design is built to withstand harsh environments as they are dustproof, durable, water-resistant, and comes with a noise-cancellation feature which allows frontline workers to hear instructions clearly even in factory noise.

- These devices come with a scanning feature which allows scanning and verification of products, all in a single headwear.

- RealWear devices provide fast connectivity options like Wi-Fi and Bluetooth which offer smooth and easy synchronization with other devices and systems.

RealWear’s Impact on Dropslab Technologies

At Dropslab Technologies, we make use of the power of RealWear to leave behind the cumbersome paperwork and distractions, and move towards a voice-activated quick fix for our industrial problems. RealWear amplifies our solutions by allowing the frontline workers access to digital work instructions and checklists directly on their devices making sure that they have accurate and latest information at their fingertips. It helps in reducing errors and improving efficiency by 40-60%.

They can capture pictures, voice notes, and videos which are directly synchronized with other devices and systems. This helps in instant analysis and response to make sure if there are any problems which can be solved instantly. The video streaming feature of RealWear enables frontline workers to connect with remote experts through live chats for troubleshooting and problem-solving. For example, a global consultancy has decreased its travel costs by 75% through remote construction inspections and troubleshooting, improving quality without having to travel.

The instant and real-time capture through RealWear devices improves tracking and makes sure that the rules are being followed by providing a clear audit trail and transparency at each step as everything is documented and verifiable in our system Dropslab Core. RealWear allows factory workers to use both hands while completing tasks without any distractions which improves efficiency.

Summary

In summary, RealWear significantly elevates Dropslab Technologies’ operational efficiency and safety standards by including advanced wearable technology into our processes. Its features including voice commands, hands-free operations combined with smooth synchronization with our applications allow us to provide quality control, traceability, and work instructions to workforce so industries can achieve maximum efficiency and minimal downtime.