How Dropslab’s Dropslab Sense is Transforming the Industry

The industrial sector has seen a remarkable transformation with the rise of foundational technologies like artificial intelligence (AI) and augmented reality (AR) and is now moving towards industry 5.0 as discussed in the past. Before this transformation, specialized models were required for individual tasks which resulted in complex integration challenges and took a lot of time for implementation. However, with the emergence of these intuitive solutions like Dropslab Sense, industries are now benefitting from simplified processes that can provide real-time digital workflows, maintenance, assembly, quality control, and other services.

Similarly, Dropslab Technologies is not behind. Our intuitive AI and AR-powered solutions assist your frontline workers in viewing real-time instructions by using AR headsets, smartphones, or tablets to assemble your products. For example, a worker is assembling an engine block, and he keeps on forgetting his next step or continuously goes back and forth between his task and paper-based manual. This not only increases the downtime but due to divided focus, puts the frontline worker in harm’s way. To prevent this Dropslab offers its Dropslab Sense which can be synchronized with AR glasses so factory workers can go hands-free, and view instructions and the exact location to fit the parts, reducing assembly time by 15%.

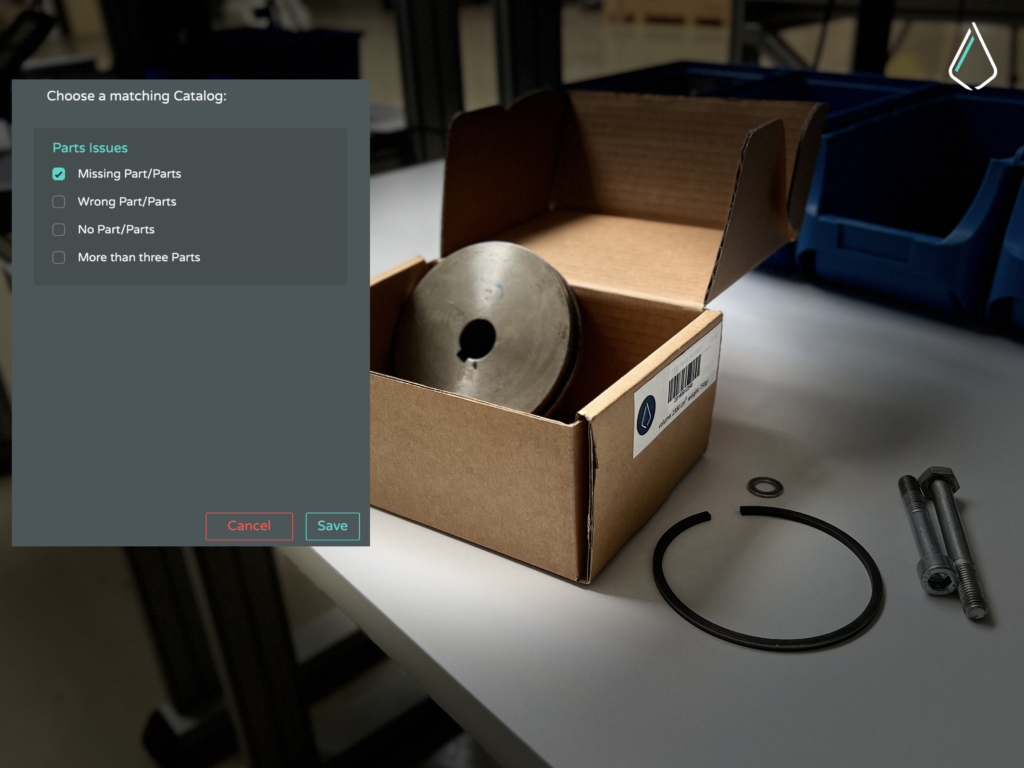

Also, our failure catalog in Dropslab Sense, speech-to-text, voice commands, and other such features help with predictive maintenance. It is estimated that maintenance powered by artificial intelligence can decrease unexpected downtimes by 60% which saves manufacturers and owners a notable amount of costs and time. As per a McKinsey report, using these new technologies based on artificial intelligence can benefit up to $1.5 trillion (about $4,600 per person in the US) annually in the automotive industry by 2030 as these solutions maximize productivity and save costs across multiple stages, from design to maintenance.

The automotive manufacturing sector can also benefit from AR’s immersive capabilities within the Dropslab Sense as the industry workers in the production line can use the intuitive solutions to view interactive 3D models of parts before assembly and see how to assemble each part making sure that there is no error in proper alignment and fitting. It decreases assembly errors, speeds up production, and enhances quality assurance. By combining AR and AI in an organized way, Dropslab is not only improving maintenance and quality control but also changing how vehicles are built. Dropslab is playing a key role in offering a safer, more efficient, and more productive manufacturing environment for workers to complete their tasks.

About Dropslab Technologies

To assist manufacturing organizations like the automotive industry in achieving their objectives regarding quality and efficiency, Dropslab provides a robust labor management platform. Our primary expertise lies in optimizing work processes using the Dropslab Technologies Workforce platform. This involves implementing intelligent and error-free procedures, leading to an average 15% gain in productivity. Through parallelization and contextual workflows, this results in a decrease in “non-value-added activities” within the operation’s supply chain. Employees can use smart glasses or other devices to get hands-free contextual assistance, documentation, and remote help from experts. Our platform offers the resources required to achieve these goals, including the ability to create personalized work instructions, manage assignments effectively, and visualize processes. Industries can improve efficiency, simplify processes, and achieve overall success in workforce management projects by using Dropslab’s solutions such as Dropslab Sense.