How to Produce Efficient Digital Work Instructions

In any sector when it comes to floor workers, work instructions are extremely important. These make sure that all the tasks are performed correctly and timely. This reduces the chance of mistakes and improves safety. Moreover, if the work instructions are written in a way that they are easy to understand then it can also help in speeding up the process by providing straightforward instructions.

Yet still there are way too many organizations which create and use work instructions which are confusing and difficult to understand, leaving their workers frustrated and unable to complete tasks on time. This also leads to errors, and lower productivity. So, what is the best way to create work instructions that will notably improve efficiency and accuracy of the tasks? And why should we leave the traditional work instructions and shift to the digital ones?

Don’t worry, in this article you will get all the details on how to produce efficient digital work instructions, and what are the reasons that you should shift to the digital work instructions.

Steps to Produce Efficient Digital Work Instructions

To produce effective digital instructions, you must remember a few points. If you keep them in mind and produce your work instructions, you will achieve all your goals. Here are the things you should always remember when producing efficient digital work instructions.

Understand the Process

Understanding the tasks and processes is important. For example, breaking down assembly of a car engine into collecting its components, then joining them, performing inspections, running tests, and so on can help in understanding the process better. This breakdown of the complete process into individual tasks can help in understanding the workflow, discovering important steps, and finding out the best way to display each task. Moreover, collaborating with experienced workers and process engineers while making the DWIs can help in making sure that all the necessary steps, possible problems and their solutions are included in the work instructions.

Select Appropriate Technology

You should always select the devices that are suitable for your work environment. Tablets, smartphones, and wearable devices like RealWear are generally used for delivering digital work instructions. Also, use the software that supports the content you want to display, your real-time updates, and synchronization with other digital systems. Moreover, make sure that the software you are using is easy to understand, user-friendly, and can be customized depending on the workers’ preferences.

Create Clear and Concise Instructions

Generate instructions in a way that they are clear and provide information for each step of the task being performed. Use simple language so novice and experienced, all workers can understand and avoid unnecessary information or words that might confuse the workers. Use images, videos, diagrams, and other visual aids to show how the worker can complete difficult tasks. These can improve understanding and process execution accuracy.

Incorporate Interactive Elements

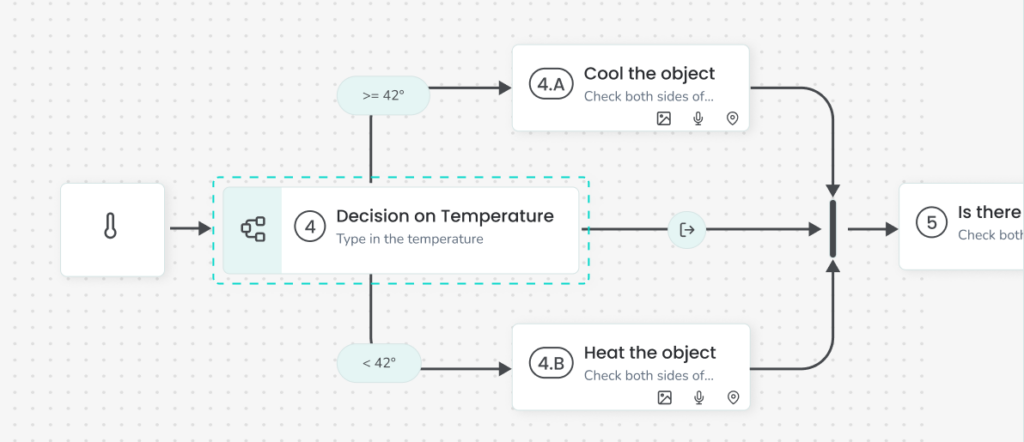

Include interactive elements such as checklists to make sure each step is performed accurately. Also, incorporate interactive forms which can document information directly from the workers while providing real-time feedback. Include decision trees in your work instructions so workers can get guidance when facing multiple situations. This enables them to handle unexpected issues or deviations effectively.

Ensure Real-Time Accessibility

Use cloud dependent on platforms to make sure that work instructions are accessible in real-time through any device. It can enable instant updates and makes sure that all the workers have the latest information. Also, make sure, if there are connectivity problems then the DWIs are also available offline. This will help in preventing downtime due to internet connectivity issues in various industrial environments.

Test and Validate

Perform periodic pilot testing with a small group of workers to find out if there are any areas for improvements or issues with the DWIs. Get their feedback on the clarity and effectiveness of instructions. This way if there are any changes required you can make those so the workers can easily use the DWIs, and you get smooth and efficient task management.

How to Use DWIs on the Shop Floor?

Now that we know how to create effective digital work instructions, let’s see how they are used on the shop floor. First, you must ensure all workers have access to DWIs system. You can use RealWear glasses, smartphones, computers, or tablets to let your workers access the DWIs. After the workers have access to the DWIs, you must train them on how to use these. Your training should include the following objectives:

- How to use the system

- How to find the DWIs for specific tasks

- How to find information within these instructions

- How to mark errors or inconsistencies in the instructions

After the workers are trained on how to use these DWIs, they are ready to work using these instructions for their everyday tasks. When workers are unclear about how to finish a task or want clarity at any stage, they should use the system. Workers should be encouraged to provide ideas to the team in charge of system maintenance if they have any thoughts for how to make the DWIs better. You may make sure that the work instructions are up to date and correct for the workers on the shop floor by regularly examining and revising them.

If designed and used properly, digital work instructions may be a very useful tool for teams working on the production floor. You may design DWIs that are easy to read, understand, and customized to your team’s demands by following the methods listed in this article. The process doesn’t finish here, though; to keep the work instructions correct and current, be sure to check and update them frequently.

Why Shift from The Traditional (Paper) Work Instructions?

Work instructions were drafted and produced on paper for many years. Although this approach was quite effective, it had several shortcomings, such as:

- Having Trouble Updating: It was frequently difficult to update the paper-based instructions and make sure that everyone received the most current version of the work instructions when changes were necessary.

- False Information: Paperwork instructions can easily become inaccurate and outdated over time. Team members may follow the wrong processes, which may result in mistakes and doing the tasks again.

- Lack of Visibility: Managers may find it challenging to keep track of who is doing what and how well when working with paperwork instructions. It may be difficult to pinpoint places that need improvement due to this lack of visibility.

- Easily Misplaced and Lost: You will require more specific work instructions as your operations and goods expand. It will get harder for operators to locate and review the appropriate information if you have a lot of paper-based work instructions.

- Limited Scope: Having a large variety of product variations with an infinite number of combinations can make the following paper-based work instructions restrictive. Making precise paper-depended work instructions for each unique order might be nearly impractical in a configure-to-order/customization setting.

The good thing is that work instructions can now be created and managed more effectively. The problems with traditional paper documents can be solved by employing digital work instructions.

In Summary

Producing efficient digital work instructions involves a thorough understanding of the manufacturing process, careful selection of technology, and continuous refinement based on user feedback. By following these steps, manufacturers can create DWIs that significantly improve productivity, minimize errors, and enhance overall task management and production efficiency.