Production Management with Dropslab’s Advanced Tools

When it comes to manufacturing, the process is simple, it includes sourcing raw materials and transforming them into finished products. Simply put, manufacturers add value to the raw materials by turning them into an end-product that an end-user may utilize or consume. Manufacturers have a keen interest in advanced methods and procedures like using tools for easy data processing, accurate decision making, and much more used in producing goods in their industry so they can adhere to the requirements and desires of their customers. This is known as production management.

To put it simply, production management is the act of overseeing the resources needed to convert raw materials into final goods while keeping an eye on the whole lifetime of the product. Naturally, these resources differ, including everything from personnel and supplies to the different kinds of equipment utilized at different sites.

Production Management vs Operations Management

Operations management is another term that is frequently brought up while talking about the management of production processes. Regardless of their similarities, operations management and production management are not the same. Below, you can learn the difference between the two terms and their usage.

| Aspect | Production Management | Operations Management |

| Definition | Focuses on the effective use of essential resources to produce products for clients. | It is a broader concept that covers both production-related and routine tasks of a factory. |

| Scope | Mainly deals with making products in factories. | Covers all manufacturing facilities of all sizes and industries, along with routine tasks and processes. |

| Focus | It ensures that the right amount of quality products is being produced at the lowest costs to meet customer requirements and needs. | It ensures that resources are being effectively used to keep customers satisfied and the industry running smoothly. |

| Relation | It is a part of the larger concept of operations management. | Includes production management as one of its essential components. |

| Industrial Application | Mostly used within the manufacturing industry. | Used in many different industries, including manufacturing. |

Why is Production Management Important?

Production management is a crucial tool that manufacturers must use as it focuses on operations at the factory level. As a result, a manufacturing company must monitor every action involved with related operations. Several crucial factors that emphasize the significance of production management are given below:

1- It Reduces Manufacturing Costs

If a manufacturing process uses an excessive amount of money to produce a product for the consumers, it might not generate enough revenue for the industry. In these situations, industries usually face downfalls as they are unable to work efficiently. Therefore, manufacturers need to use production management systems so they do not face excessive financial instability. It can help them optimize their processes by analyzing them so non-value-adding tasks can be removed which lowers the production costs and increases the profit.

2- It Optimizes the Use of Resources

Through production management, factories can easily analyze the resources needed to produce a product. For example, industries must track and monitor their workers, equipment, and machinery, and manage inventory and raw materials so there are no excess materials or delays. This allows them to optimize their resource usage making sure that only the essential resources and steps are being used to produce the end product. It removes the lean waste and makes the production line more profitable and competent.

3- It Enhances Competitiveness in the Market

Competitors in the manufacturing industry are constantly competing for market share in any type of market whether it is manufacturing, logistics, retail, etc. If factories are unable to compete head-on with their competitors, then the industry goes down. Through production management, can make sure that they are continuously producing high-quality goods that satisfy customer requests. This improves consistency in the production line, allows the industry to meet customer demands, and improves the market presence.

4- It Helps in Meeting Set Targets and Objectives

As previously stated, production management is a part of operations management. In operation management, executive-level tasks are involved in analyzing market conditions to identify the goals and targets that a factory must accomplish to continue its production. At the lowest level, production management takes over as it improves the manufacturing processes to achieve those defined objectives. With effective management, the industry meets or surpasses customer expectations while producing high-quality products at reduced prices. It enhances customer satisfaction and makes the production line near ideal.

Benefits of Using Dropslab’s Production Management System

In the current industrial era of Industry 4.0, production management continues to prove its importance. However, with the dynamic industrial environment in the present market, the practice and implementation of production management systems are very different. Manufacturers can benefit greatly from using production management systems or platforms like Dropslab Core and Dropslab Sense. They provide several benefits which include:

1- Intuitive User Interface (UI)

There is not much time for training or learning new things in an industry, especially for frontline workers. Thus, by using user-friendly systems, managers and supervisors can save a lot of time that comes with training and it also enables them to easily schedule daily tasks by using these tools, which remove the need for constant manual checks during the day.

2- Detailed Customization

Through Dropslab’s production management solutions, manufacturers can easily tailor their systems by creating tasks and steps that meet their requirements. For example, if a factory needs digital workflows with failure tracking, or if they want to include any media, they can do that with Dropslab Core.

3- Comprehensive Analytics

To manage a production line, multiple types of data are required so that managers can get the essential information and make decisions. However, with smart factories, the massive amount of data requires proper analysis to make informed decisions. A production management system like the one provided by Dropslab Technologies enables industries to get detailed insights and information for different metrics for their production line simply through the dashboard. This not only assists in making informed decisions but also allows managers to see how the workers are performing each task by stating the time of completion, errors in a task, average cycle times, etc.

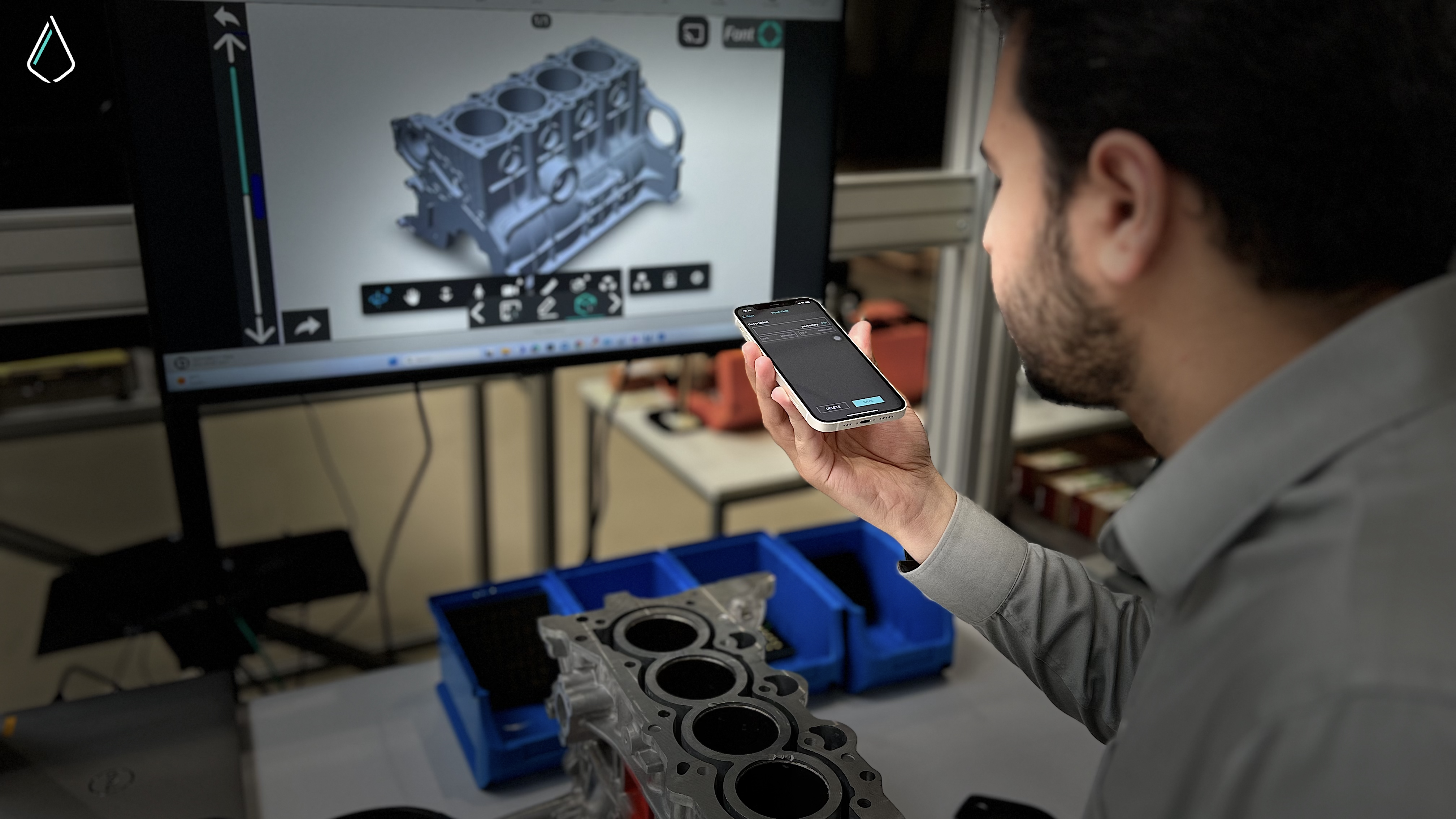

4- Shared Access

The traditional strategies to optimize a production line were excessively disconnected and are now being replaced by advanced digital production management systems that provide remote assistance as well as connectivity. These systems are cloud-based and AI-driven which allows frontline workers to have instant access to task instructions through various smart devices, supervisors and managers to have access to data from anywhere, and for workers to connect with specific personnel when needed directly. These new features and methods allow better collaboration among departments which enables better planning and management.

Summary

Effective production management is important for manufacturers who are looking to simplify their processes, reduce costs and stay on top in the today’s competitive industrial environment. With integration of tools like Dropslab’s task and production management systems, industries can easily achieve their goals. They can ensure consistent quality, meet market demands, and set themselves apart in a competitive market.