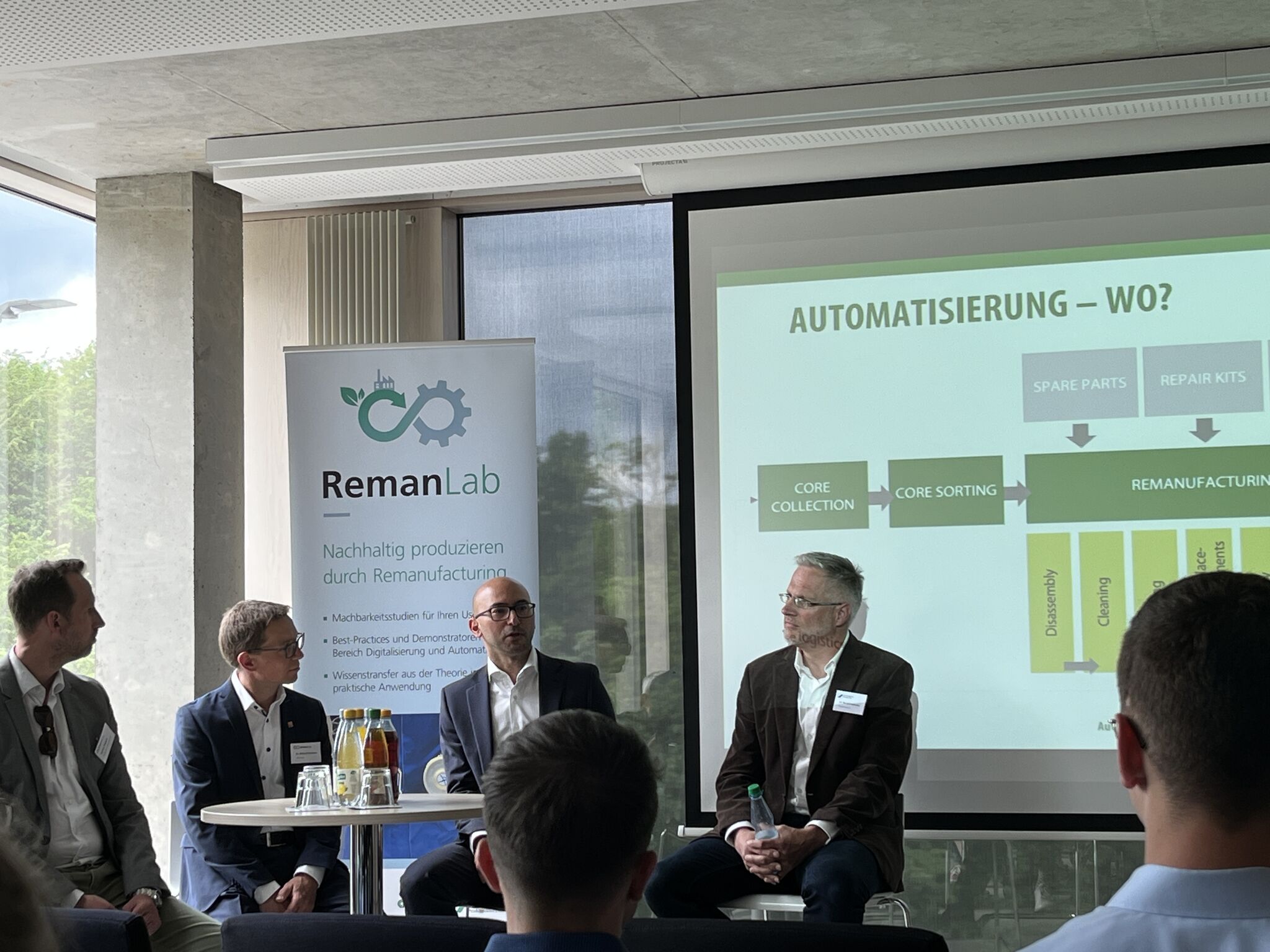

Our CEO, Dr. Meysam Minoufekr had the privilege of participating in a panel discussion at the opening of the ReMan-Lab at Fraunhofer IPA Bayreuth. It was a highly successful and engaging event organized by Prof. Dr.-Ing. Frank Döpper and his team. Here are our key takeaways:

Remanufacturing exhibits a lower degree of automation compared to the production of new parts. This is primarily due to technical, economic, and legislative barriers. Technically, the diversity of products and variations, complex dismantling and assembly processes, and the need for manual skills pose challenges. Moreover, there is a lack of expertise and workforce in this field.

In the remanufacturing process, steps such as incoming inspection and inspection itself still heavily rely on human expertise due to the high variability involved. This is precisely where Dropslab can make a significant contribution with its AI-based solution. By augmenting human capabilities, our solution helps make work processes more efficient while enhancing quality, thereby ensuring stable operations.

As the demand for remanufactured products continues to rise, intelligent solutions in remanufacturing become inevitable. The increasing customer preference for refurbished products underscores the need for such advancements.